Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Etching Patterns On Polymers With Enzyme Inks

Biomaterials: New lithographic technique could create deep, well-defined trenches and holes in polymers for biological and medical devices

by Prachi Patel

July 12, 2013

Some enzymes can chew through synthetic polymers. Researchers would like to harness this ability to etch channels, trenches, and holes into biocompatible materials as a way to fabricate drug delivery devices, scaffolds for growing tissue, and microfluidic chips. Now, one team reports two simple writing techniques—one using a stamp and the other a microscopic pen tip—to enzymatically etch tiny features on a polymer (Biomacromolecules 2013, DOI: 10.1021/bm400552u).

The techniques involve depositing an enzyme on a polymer surface in patterns using a stamp or tip coated with the protein. The enzyme degrades the polymer underneath, leaving behind the desired etched pattern.

This method is the latest version of enzyme-based lithography, which was first introduced in 2003. The techniques developed until now involve chemically attaching the enzyme to the writing instrument, such as an atomic force microscope tip. Researchers have to hold the tool in place on the polymer surface until the enzyme degrades the polymer. This process is time consuming and etches at most a nanometer down into the surface.

Richard A. Gross of Rensselaer Polytechnic Institute and his colleagues wanted to expand the capabilities of these lithographic methods and carve deeper features into polymers. To do so, the team found a way to apply the enzyme without chemically attaching it to a writing tool.

They worked with the enzyme lipase B, produced by the yeast Candida antarctica, because it degrades the polymer polycaprolactone (PCL). The Food and Drug Administration has approved PCL for making stents and drug delivery devices.

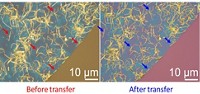

The researchers used a cotton swab to coat a solution of the enzyme on a polydimethylsiloxane (PDMS) stamp patterned with 20-µm-wide ridges. The researchers then pressed the stamp on a 300- to 500-nm-thick PCL film that they had deposited on a silicon wafer. The stamp’s ridges created stripes of the enzyme on the film. The team then allowed the enzyme to break down the polymer by incubating the PCL film at 37 °C and controlled humidity for up to 25 days. The resulting etched trenches were 20 µm wide. Longer incubation times produced deeper trenches: The enzyme dug all the way down to the silicon wafer after 25 days.

The second writing technique involved dipping a 10-µm-diameter PDMS pen tip into the enzyme and depositing dots of the enzyme onto the PCL film. After incubation, the team could make patterns of holes as small as the diameter of the tip.

Other groups hadn’t tried transferring free enzymes to polymer surfaces, because the conventional thinking was that the proteins would diffuse sideways and produce messy features, says Gross, who conducted the work while at Polytechnic Institute of New York University. But the features made with the new techniques were clean and matched the designed patterns. The researchers don’t fully understand why the enzyme only carves down vertically into the PCL and not horizontally, but they think that the strong affinity between the enzyme and the polymer keeps the proteins from diffusing away.

Hua Zhang, head of the materials science division at Nanyang Technological University in Singapore, calls the two techniques simple and versatile. He adds that if the researchers can improve the patterning speed and resolution, the methods could be ready for practical applications.

Alan M. Lyons of the College of Staten Island, who worked with Gross on this project, says that they’ve already sped up the process to under 10 minutes, including incubation time. They’re now testing the technique on other enzyme-polymer systems and attempting to make smaller features.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter