Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Printing High-Performance Circuits With Carbon Nanotubes

Electronics: A new fabrication process lays down arrays of nanotube transistors for flexible displays

by Katherine Bourzac

August 16, 2013

Silicon chips are at the heart of most electronic devices, but replacing silicon with nanotube electronics would enable flexible displays and large-area sensors, needed for applications where light weight and bendability are important. Now, researchers have developed a printing technique that deposits high-performance carbon nanotube transistors on flexible sheets of plastic (Nano Lett. 2013, DOI: 10.1021/nl401934a). The nanotube electronics perform well and can be manufactured on a large scale.

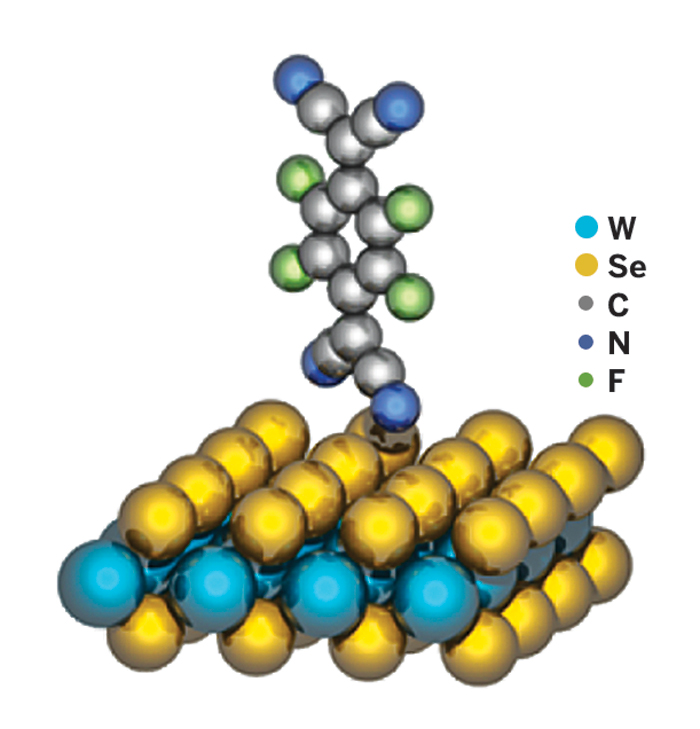

Manufacturers make conventional silicon electronics using photolithography, where they deposit various materials onto silicon and then etch them away to form patterned circuits. But printing circuits is key to making flexible, large-area devices at a reasonable cost. For electronics that use nanotubes, it’s difficult to get both printability and good performance, says Ali Javey, a materials scientist at the University of California, Berkeley. So Javey and his colleagues developed a process to make nanotube transistors at room temperature with a gravure printer, the same technology used to print magazines. The secrets to achieving the high-performance printed transistors are the right combination of materials and laying down the most sensitive components—the nanotubes—first, Javey says.

The researchers started by placing a sheet of polyethylene terephthalate (PET) in a 99% solution of semiconducting carbon nanotubes for two hours. They then rinsed and dried the plastic sheet, revealing a random, dense network of nanotubes that coated the sheet. Some earlier printing methods lay down the nanotubes as the top layer, rather than on the smoother bottom surface. Because of that, the quality of the finished devices suffered, says Javey.

To make transistors, the Berkeley group turned to a custom-made gravure printer. The printer consisted of a rolling drum mounted with the nanotube sheet and a set of flat, patterned masks loaded with various electronic inks—one mask for each material needed to make the transistors. First, the printer rolled the nanotube sheet over a mask loaded with silver nanoparticle ink to print the source and drain electrodes for the transistors. Then, the researchers printed the gates—components that switch the transistors on and off—with a composite of poly(methyl methacrylate) and barium titanate nanoparticles, a dielectric material. Previous nanotube electronics used dielectric materials that printed well but were not good electrical insulators, Javey says. Finally, they printed another electrode with the silver nanoparticle ink.

Electrons can move through the finished devices at 10 cm2 per volt-second, about 10 times faster than through other printed nanotube transistors. The higher the electron mobility, the lower the applied voltage required to switch the transistor. In some applications, this saves energy; in others, it’s a necessity. In flexible displays, for example, such transistor arrays are used to switch the lighted pixels on and off. The mobility of the electrons in those transistors determines the brightness of the picture.

Zhenan Bao, a materials scientist at Stanford University, is impressed by the performance of the transistor arrays. However, she notes that the most important component of the devices, the nanotube layer, has not been printed. Javey says one of his group’s next steps is to adapt the process to a roll-to-roll printer, where cylindrical masks roll over a continuously fed sheet of plastic. Unlike gravure printing, a roll-to-roll system should be able to deposit the nanotubes onto the plastic sheet—and it will also be faster.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter