Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Confined Iron Converts Methane

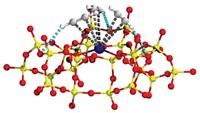

Lattice-confined single catalytic sites in a silica matrix enable direct conversion of methane to hydrogen, ethylene, and aromatics

by Stephen K. Ritter

May 12, 2014

| A version of this story appeared in

Volume 92, Issue 19

A new type of heterogeneous iron catalyst can directly convert methane into higher hydrocarbons without forming deactivating coke deposits or unwanted carbon dioxide (Science 2014, DOI: 10.1126/science.1253150). If optimized to work on an industrial scale, the catalyst would provide a more economical and environmentally friendly means for converting abundant natural gas into fuels and chemicals. The standard approach to upgrade natural gas, which is mostly methane, is to oxidize it to synthesis gas—a mixture of CO and H2—and from there make methanol and then light olefin feedstocks such as ethylene. Direct conversion of CH4 to ethylene and higher hydrocarbons would be better, but the C–H bonds in CH4 are not terribly reactive. And after cleaving the first C–H bond, suppressing complete dehydrogenation and overoxidation is a challenge. Building on its prior work on encapsulated iron catalysts, a team led by Xinhe Bao of China’s Dalian Institute of Chemical Physics prepared the new catalyst by fusing iron metasilicate (FeSiO3) with silica (SiO2) at 1,700 °C, followed by leaching the material with nitric acid. Lattice-confined single iron sites in the catalyst activate CH4 in the absence of oxidants, generating methyl radicals that then undergo gas-phase reactions to yield ethylene, benzene, and naphthalene as the only products. The trick is the absence of adjacent iron sites, which prevents uncontrolled catalytic C–C coupling.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter