Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Sound Waves Shake Pharmaceuticals Into Cocrystals

Chemical Engineering: Resonant acoustic mixing provides a green, scalable way to cocrystallize compounds

by Sarah Webb

February 6, 2014

| A version of this story appeared in

Volume 92, Issue 6

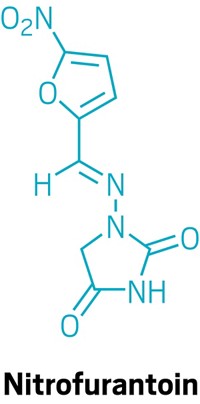

Ideally, the active ingredient of an oral medication should readily form crystals, dissolve quickly in the digestive tract, and be rapidly absorbed in the body. If a compound can’t do those things on its own, scientists can help it by crystallizing the compound with one or more other compounds, forming cocrystals with the desired properties.

Now, researchers report that vigorously combining compounds using intense sound waves—a technique known as resonant acoustic mixing—could provide a green and scalable way to produce pharmaceutical cocrystals (Org. Process Res. Dev. 2014, DOI: 10.1021/op4003399).

Traditionally, chemists have produced cocrystals either by crystallizing the compounds together out of a solution or by grinding the chemicals together mechanically with a mortar and pestle or a ball mill. Mechanical methods limit the use of solvents and are therefore more environmentally friendly. But they are also difficult to carry out on the multikilogram scales needed in the pharmaceutical industry.

Jerry S. Salan, CEO of Nalas Engineering Services, in Centerbrook, Conn., thought of a way around this roadblock. He knew that resonant acoustic mixing produces enough force to combine and coat powders, so he wondered whether that force also could produce cocrystals. Acoustic mixers use high-intensity sound waves to transfer mechanical energy to the materials being mingled. The waves vibrate the materials inside a sample vial with forces 10 to 100 times that of gravity.

As a proof of concept, researchers at Nalas placed the anticonvulsant drug carbamazepine and the coformer compound nicotinamide along with a small amount of solvent into a resonant acoustic mixer. After one hour, the combination readily formed cocrystals that matched the quality of those formed by other methods. The researchers successfully produced cocrystals on a variety of scales, using 100 mg, 1.5 g, and 22 g of the solid starting materials.

Resonant acoustic mixing provides a way of screening cocrystallization conditions with various compounds and doesn’t need a lot of solvent, says Nalas’s David J. am Ende. Commercially available resonant acoustic mixers come in capacities up to 200 L, which should be sufficient for pharmaceutical-scale operations, the researchers say.

Over the past decade, pharmaceutical companies have realized that cocrystallization could offer a way to make better medicines, says Mike Zaworotko of the University of Limerick, in Ireland. “This paper addresses one of the major hurdles of how to make cocrystals on a larger scale,” he says. Further research will be needed to confirm that the process will scale up and to determine if this technique will apply to a range of compounds, he adds.

Nalas has filed a provisional patent for the cocrystallization process. It is seeking a commercial partner to help carry out additional studies needed to scale up the method.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter