Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Simple Technique Transfers Clean Graphene Sheets

Materials Science: A novel method allows engineers to build graphene-based electronics with good performance

by Kate Greene, special to C&EN

February 13, 2014

| A version of this story appeared in

Volume 92, Issue 7

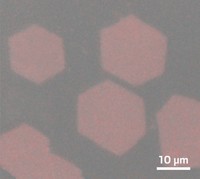

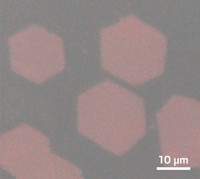

Graphene has a dirty little secret. When researchers build electronic devices with it, the standard process they use to move sheets of the delicate, single-atom-thick material into place can lead to contamination or damage that reduces device performance. But now, researchers in Taiwan have developed a simple and elegant way to transfer graphene that keeps the material clean (ACS Nano 2014, DOI: 10.1021/nn406170d).

Scientists produce high-quality, large-area sheets of graphene by growing them on copper surfaces using a method called chemical vapor deposition. Unfortunately, removing the graphene from the copper substrate is where the contamination problems start, says Chih-I Wu, an electrical engineer at National Taiwan University.

The most commonly used transfer method relies on a polymer-based material to hold the graphene in place while the metal below is etched away. The polymer, however, leaves behind a residue that contaminates the graphene. And cleaning it often damages the graphene so it doesn’t perform optimally, Wu says.

His team reports a cleaner approach that starts with submerging a copper substrate and its attached graphene in a petri dish filled with a metal-etching solution. The solution frees the graphene, which then floats on the surface. The researchers replace the etching solution with a mixture of isopropyl alcohol and water. Next, the researchers slip the device they’re building below the floating graphene sheet. The researchers then remove the alcohol-water mixture, lowering the graphene onto the device.

Using this transfer method, the researchers made a series of devices, including a transparent organic solar cell and graphene-based transistors. Electrical charges could move 50% faster through the transistors than in those made with graphene transferred by polymer.

Rodney S. Ruoff, a nanoengineer at the University of Texas, Austin, calls the approach interesting and useful. He suggests it could be used to make a type of low-power transistor called a BiSFET, which ideally needs very clean graphene.

The researchers plan to scale up the method and test the approach with 8- or 12-inch-diameter silicon wafers.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter