Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Photonics

Simple Process Creates Near-Perfect Mirrors Out Of A Metamaterial

Photonics: A layer of self-assembled particles allows researchers to etch an almost-perfect reflector that might be used in telescopes and lasers out of silicon

by Katherine Bourzac

June 15, 2015

Highly reflective mirrors help telescopes capture images of faint, distant galaxies and enable lasers to produce intense beams of light. Researchers have come up with a new way to make such mirrors, by starting with self-assembled nanoparticles. These near-perfect reflectors demonstrate the promise of metamaterials, a relatively new class of materials designed to interact with light in novel ways (ACS Photonics 2015, DOI: 10.1021/acsphotonics.5b00148).

The common type of mirror, the kind found over bathroom sinks, is a piece of glass backed by a smooth aluminum film and reflects about 90% of visible light—good enough for checking your outfit. But high-performance applications, such as telescope lenses or the reflective cavities in lasers, need more efficient reflection—even a very small absorption of light by the mirror will degrade performance. So these instruments use Bragg reflectors—stacks of thin films that refract light in such a way as to reflect almost 100% of incident light at the wavelengths of interest. But they are costly to produce.

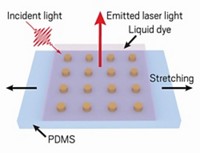

Last year, Jason Valentine, a mechanical engineer at Vanderbilt University, and colleagues demonstrated a third kind of mirror—a metamaterial—that combined the simplicity of metal films with the near-perfection of Bragg reflectors (Appl. Phys. Lett. 2014, DOI: 10.1063/1.4873521). Metamaterials are engineered to have properties, typically derived from nanoscale patterning, that do not occur in the bulk material. They made their reflector by patterning a silicon wafer’s surface with an array of silicon cylinders a few hundred nanometers in diameter. Each of the cylinders acted like a tiny resonator for particular light frequencies—analogous to the way certain sound frequencies will make a tuning fork hum. By adjusting the size of the cylinders, Valentine could control how well they reflected light of a given frequency. This mirror reflected more than 99% of light at the peak wavelength.

Although the work showed that metamaterial mirrors could be effective, the method for making them was far from practical: The researchers painstakingly created the arrays using electron-beam lithography, which is difficult to scale up. So Valentine and his team adopted a simpler method to make bigger, near-perfect reflectors.

They started with off-the-shelf polystyrene beads 820 nm across and dropped them into a film of water. Driven by electrostatic forces, the beads self-assembled into a monolayer on the water’s surface with a repeated hexagonal pattern. Valentine’s group then drained the water, lowering the bead layer onto a submerged silicon wafer, and used a plasma etching process to shrink the beads to 560 nm. Finally, they used the bead layer as a lithographic mask to pattern the underlying silicon. The resulting 2-cm2 arrays were covered in silicon cylinders, each 335 nm tall and 480 nm across the top.

The arrays reflect 99.7% of incident infrared light at 1,530 nm. Valentine is now working on making larger area reflectors by patterning with silicon nanospheres.

“This is a phenomenal result, especially for something made by self-assembly,” says Michael B. Sinclair, who develops metamaterials at Sandia National Laboratories. Bragg reflectors are an established technology that will be difficult to compete with anytime soon, he says, but the work is “an impressive step forward for making large-area metamaterials.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter