Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Soldering without heat

Spontaneously formed shell on microscopic alloy droplets keeps them in liquid state until shell is ruptured for applications

by Mitch Jacoby

March 11, 2016

| A version of this story appeared in

Volume 94, Issue 11

An advance in composite materials might spell the beginning of the end for soldering irons, those age-old workhorse tools used in electronics manufacturing and do-it-yourself electrical repairs. A research team used simple chemical reactions to encapsulate liquid droplets of alloys in a thin shell that prevents the liquids from solidifying even at temperatures well below their melting points (Sci. Rep. 2016, DOI: 10.1038/srep21864). By applying gentle force to the droplets, the scientists could break them open and use them to solder metal parts without the need for electricity or heat.

Undercooling, the phenomenon on which this advance is based, is not new, according to Iowa State University materials scientist Martin Thuo, who led the team. But because undercooled materials are unstable and difficult to prepare, most studies have focused on these materials’ thermodynamics and other fundamental properties.

Thuo’s group devised a way to overcome those hurdles and use the materials for room-temperature soldering, which could simplify and reduce manufacturing costs and minimize the chance of damaging heat-sensitive components on tightly packed circuit boards.

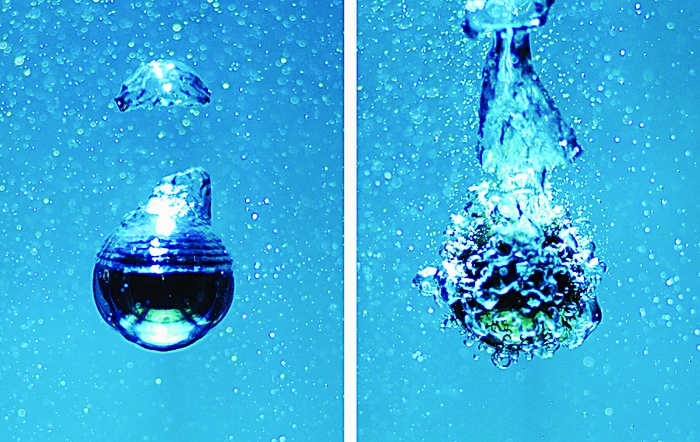

By trapping microscopic metal droplets in an ultrathin shell, Thuo’s team prevents them from coming in contact with nucleation sites needed to trigger solidification. Rupturing the shells by squeezing them gently between two surfaces or poking them with an ion beam or microscopic probe tip causes the alloy liquid to flow and immediately solidify, bonding surfaces together.

Thou’s group, which includes Simge Çinar, Ian D. Tevis, and Jiahao Chen, formed droplets of a Bi-In-Sn alloy known as Field’s metal and a Bi-Sn alloy by heating the alloys in a solution of acetic acid and diethylene glycol. The scientists heated the alloys well above their melting points, which are 62 °C and 129 °C, respectively.

The group formed microscopic droplets by whipping the molten metals into a froth with a high-speed rotary tool and then allowed the solutions to cool slowly. Thuo explains that the alloy droplets react with air in a self-limiting manner to form an oxide shell. The oxide then reacts with acetic acid, forming a smooth composite oxide-acetate shell that stabilizes the liquid core upon cooling.

In a demonstration, the team applied the core-shell droplets to a gold film, then firmly soldered a gold wire to the film by applying a bit of manual pressure. They also used the droplets to repair a hole in a thin film of silver and to bond foils together. Thuo has formed a start-up company, Safi-Tech, to commercialize the technology.

“This is a very clever way of taking advantage of what Mother Nature gives you,” says North Carolina State University chemical engineer Michael Dickey, referring to the spontaneous reactions that enabled these alloys to be used for soldering.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter