Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Zinc sponge protects rechargeable battery

Unconventional form of zinc electrode leads to low-cost, long-lasting, safe battery

by Mitch Jacoby

April 27, 2017

| A version of this story appeared in

Volume 95, Issue 18

To exploit zinc’s numerous useful properties in next-generation batteries, researchers have prepared zinc electrodes in a porous, spongelike structure. Batteries with such electrodes could be long lasting, energy dense, and inherently safe, according to a study (Science 2017, DOI: 10.1126/science.aak9991).

The relatively low cost of zinc coupled with its wide availability and favorable electrochemical properties should give zinc-based batteries a competitive advantage over other battery chemistries. In particular, Zn batteries could be safer than lithium-ion batteries because Zn ones use water-based electrolytes instead of the flammable organic kinds standard in Li-ion batteries.

But aqueous Zn-based batteries fail quickly. Upon recharging, the metal forms wiry dendrites that can grow uncontrollably and pierce the separator between the electrodes. The dendrites can then connect the positive and negative electrodes and short-circuit the battery.

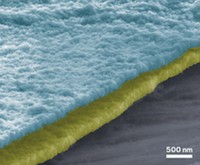

Scientists at the Naval Research Laboratory in Washington, D.C., have shown that those problems can be bypassed by using zinc electrodes with a spongelike structure instead of conventional pressed-powder electrodes.

The team, which includes Joseph F. Parker, Debra R. Rolison, and Jeffrey W. Long, prepared the zinc sponges by adding zinc powder to an emulsion of oil and water and then allowing the mixture to dry overnight.

The sponge structure leads to more uniform oxidation of the zinc metal during discharge and, consequently, a more uniform coating of the discharge product (zinc oxide) on the sponge anode. Likewise, the structure makes the reverse reaction during charging—ZnO reduction to metallic Zn—more uniform.

Even when 90% of the zinc is oxidized during discharge, Parker notes, the sponge retains a metallic zinc core. The core causes electric currents to be distributed uniformly throughout the sponge, making it physically difficult to form dendrites, he adds.

The team found that the sponge electrodes protected a Ni-Zn battery when it cycled repeatedly between charging and discharging under demanding current conditions that induce dendrite formation in reference batteries. It also enabled the battery to withstand tens of thousands of cycles required for “start-stop” microhybrid vehicles.

Braun notes that the Naval Research Laboratory team “has found a particularly compelling system, where the 3-D electrode structure provides high power, as expected, but perhaps surprisingly, results in dendrite suppression and thus very good long-term cycling.”

He adds, “This discovery is particularly useful because it is accomplished with an intrinsically safe, Earth-abundant, and relatively high-energy-density nickel-zinc chemistry.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter