Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Recycling

Ultrasound boosts battery recycling

Rapid process recovers valuable metals from old electrodes

by Mark Peplow, special to C&EN

July 9, 2021

| A version of this story appeared in

Volume 99, Issue 25

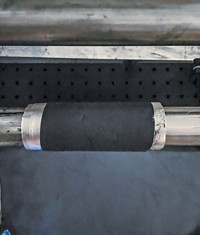

A blast of ultrasound could help recycle lithium-ion batteries by stripping valuable materials from spent electrodes in mere seconds (Green Chem. 2021, DOI: 10.1039/d1gc01623g). A key goal of battery recycling is to recover metals like lithium, nickel, and cobalt from the active material that coats the batteries’ foil electrodes. Recycling currently relies on pyrometallurgical smelting, which is energy intensive and expensive, or hydrometallurgical methods, which involve caustic reagents. And these processes generally produce low-purity, low-value waste streams that need extensive processing. “Our approach is different, because all we’re doing is breaking the adhesive bond between the metal substrate and the active material,” says Andrew P. Abbott of the University of Leicester, part of the team behind the ultrasound process. When an electrode passes underneath a high-power ultrasonic horn, the vibrations free fragments of the electrode’s coating, leaving a clean copper or aluminum foil ready for conventional recycling. Meanwhile, the flakes of active material fall into a water bath and after filtering can be directly regenerated for use in a new electrode, without separating each element. The process takes less than 10 seconds and recovers more than 99% of the active materials, making it faster and more efficient than conventional recycling. Although the researchers disassembled the waste batteries by hand, robotics could help scale up the process, as could better battery design to make disassembly easier.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter