Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Fluorine Chemistry's Uncharted Territory

by STEPHEN K. RITTER, C&EN WASHINGTON

February 14, 2005

| A version of this story appeared in

Volume 83, Issue 7

Although the successes of fluorine chemistry were at the front of most chemists' minds at the Winter Fluorine Conference, one speaker gave the attendees a reminder that there are still a lot of unsolved challenges.

"There are some failures in fluorine chemistry," noted Bruce E. Smart, a DuPont chemist and research manager, during an invited lecture. "These topics have such potential significance in industry that they're worth talking about from time to time, to bring them to people's attention," he said.

Being from DuPont, Smart focused on fluoropolymers. These compounds are based on only a few fluorinated monomers, polymerization methods, and types of copolymers, he said. This is in contrast to the array of methodologies and types of polymers known for nonfluorinated compounds.

Coordination or metathesis polymerization methods, such as Ziegler-Natta-type reactions carried out on ethylene and propylene, have been unsuccessful with fluoroolefins, Smart said. These fluorinated monomers typically are too unreactive because they have highly electron-deficient double bonds. If they do react, metal fluoride elimination is a problem. These circumstances have limited commercial polymerizations to free-radical processes. It's also difficult to tailor high-molecular-weight block copolymer structures with fluoroolefins, he added.

Fluoroolefin polymerization is still based largely on developments from the 1950s, he pointed out, while there have been myriad changes for hydrocarbon polymerizations, particularly in catalyst design and living polymerization capabilities. That means there are many opportunities for fluoropolymers, and there are “little pieces of evidence” in the chemical literature to suggest that organometallic chemistry involving late-transition metals with the right type of ligands could make a difference. “This is an encouraging area for chemists to think about,” he said.

Smart also mentioned efforts to replace fully fluorinated alkane surfactants, such as perfluorooctyl carboxylates and sulfonates that are used in polymerization processes. These compounds and their precursors are under scrutiny as persistent molecules that accumulate in the environment. “I think in the next few years we will see a lot of work to find replacements,” Smart said. “It’s possible, with the right design, that some of these materials can be lightly fluorinated and still express the surface activity of the long-chain surfactants.”

Another interesting prospect he noted is direct fluorination reactions using fluorspar (CaF2), which is the only raw material source for fluorine in the chemical industry. “There are no direct processes that use fluorspar, except to make HF,” Smart observed.

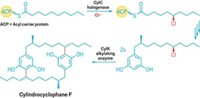

A final topic he touched on is fluorination using microbial fermentation technology. Only about a dozen organic fluorine compounds are found in nature, and so far only a single natural enzyme is known to facilitate formation of a carbon-fluorine bond. He cited the work of chemistry professor David O'Hagan of the University of St. Andrews, in Scotland, whose group isolated the fluorinase (C&EN, March 3, 2003, page 44).

O’Hagan, who attended the conference, has been working with researchers at GlaxoSmithKline to develop 18F-labeled compounds made by the enzyme that can be used as contrast agents for positron emission tomography. The St. Andrews group doesn’t yet have any fermentation studies in place, although progress is being made on site-directed mutagenesis of the enzyme, O’Hagan told C&EN. While O’Hagan didn’t speak about the fluorinase enzyme at the meeting, Cosimo D. Cadicamo in his group presented a poster summarizing work on the crystal structure of the enzyme and a mechanism for how the enzyme works [ChemBioChem, 5, 685 (2004)].

“These are all truly significant but hard problems that could almost revolutionize what’s going on in industrial fluorine chemistry,” Smart concluded. More On This Story Fluorine Rises To The Occasion From pharmaceuticals to high-tech materials, conference spotlights expanding role of fluorine

- Unsolved Problems

- Fluorine Chemistry's Uncharted Territory - FLUORINE RISES TO THE OCCASION

- From pharmaceuticals to high-tech materials, conference spotlights expanding role of fluorine

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter