Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Consumer Products

What’s that Stuff

What's that stuff? Dryer Sheets

The science that gives clothing a soft feel and fresh scent as it prevents static cling

by Linda Wang

April 14, 2008

| A version of this story appeared in

Volume 86, Issue 15

The wash cycle is complete. You toss your wet laundry into the dryer and chase it with a dryer sheet. Most people don't know how the thin sheets freshen and soften clothes or that they were developed by a chemist who wanted to help his wife out with the laundry.

In the late 1960s, Conrad J. Gaiser and his wife, Audrey, lived on the top two floors of a four-story duplex. Their laundry room was on the ground floor, and every time Audrey would wash a load, she had to run down the stairs to catch the final rinse cycle in order to add fabric softener. Liquid fabric softeners, which are commonly cationic, can't be mixed with detergents, which are anionic, because the mixture forms a precipitate.

Conrad, who had worked for a number of years in the soap and detergent industry, wanted to make his wife's life easier and got to work producing the first known dryer sheet. Laurel Gaiser, Conrad's daughter, tells C&EN how her father applied fabric softener to a piece of cotton flannel, likely from her mother's sewing room. He named his prototype Tumble Puffs, Laurel says.

In 1969, Conrad received a U.S. patent for this invention, and shortly thereafter he sold the rights to Procter & Gamble, which then marketed the product as Bounce dryer sheets.

The first version of the product had several problems, including getting trapped in the lint vent and distributing the softener unevenly onto clothes, says Gordon F. Brunner, who was P&G's associate director of research and development at the time. The company ironed out the wrinkles and launched the product nationally in 1975.

Today, many competing brands of dryer sheets are available. Each brand uses a slightly different formulation to achieve three primary goals: to soften clothes, to prevent static cling, and to deliver a fresh scent.

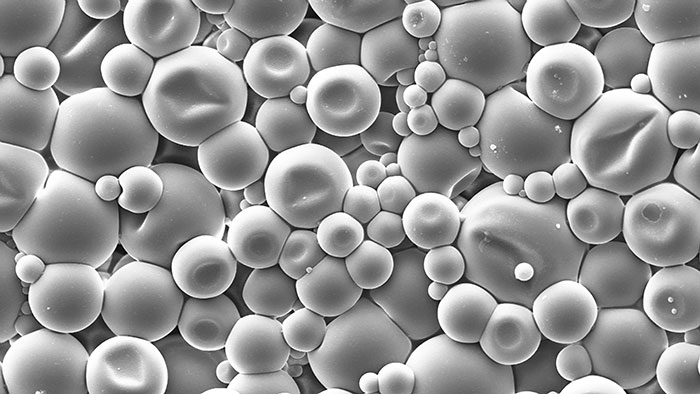

Most dryer sheets are made from a nonwoven polyester material coated with a softening agent that has a long hydrophobic chain. Fatty acids, fatty alcohols, and alcohol ethoxylates are all possible softening agents. P&G uses quaternary ammonium salts of fatty acids as its primary softening agents, whereas Unilever, which produces Snuggle dryer sheets, uses a stearic acid.

During tumble drying, the coating containing the softener melts and the compounds get transferred onto the fabrics being dried. The newly attached fatty chains give the fabric's surface a slippery feel, which people interpret as softness. The compounds also help dissipate static charge by lubricating and increasing the surface conductivity of the fabric fibers.

It's important that the softening agents have a relatively high melting point, notes Bien Santos, section head in products research at P&G. If the melting point is too low, "it will make your sheet very sticky inside the box, and you don't want that," Santos says. "What you want is something that's solid at room temperature and either softens or melts inside the dryer so you can effectively transfer it onto clothes."

Some dryer sheets also contain small amounts of inorganic compounds—such as montmorillonite, a naturally occurring calcium clay—that help control the viscosity of the fabric softener coating as it begins to melt in the dryer. "You don't want it to come off the nonwoven sheet too quickly, or you might have streaks of softener actives on some parts of the clothes and none on others," Santos says. "You want it as evenly distributed as possible."

Aside from providing softness and preventing static cling, dryer sheets also deliver a fresh scent to laundered clothes. This is done by adding fragrance molecules to the softener coating. Jack Linard, senior manager of scientific and regulatory affairs at Unilever, says that one challenge in developing dryer sheets is to minimize the amount of fragrance molecules that are lost through evaporation during the high-heat manufacturing process and in the dryer.

Linard says they choose fragrance molecules that can best survive the high temperatures inside the dryer. Moreover, they have patented a process in which the fragrance molecules are sprayed onto the substrate after the softening agents—which are heated until molten and pressed into the nonwoven fabric—has cooled. This minimizes loss of the fragrance molecule.

P&G staves off the degradation of fragrance molecules by encapsulating the molecules in cyclodextrins. In the dryer, water molecules evaporating from wet clothes help release the perfume molecules from the cyclodextrin carriers, according to Günter Wich, corporate R&D director of biotechnology at Wacker Chemie AG, the company that produces cyclodextrins for P&G.

These days, dryer sheets are no longer just used in the dryer. Consumers use the sheets for everything from polishing shoes to keeping mosquitoes at bay. P&G even has a website devoted to the off-label application of dryer sheets. Whether all the alternative applications are based on sound science is left to the reader's discretion. But one thing is for sure: The chemistry in the seemingly simple sheet packs in a lot of potential.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter