Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Separations

Membrane efficiently removes antibiotics from wastewater

Plant-based tannic acid coating adsorbs a range of molecules

by Prachi Patel, special to C&EN

November 1, 2022

An inexpensive new porous membrane can quickly remove a broad spectrum of antibiotics from wastewater efficiently and without requiring a lot of energy (Matter 2022, DOI: 10.1016/j.matt.2022.09.021).

The key behind the membrane’s effectiveness is its coating of tannic acids that adsorb antibiotics, says Orlando Rojas, a chemical and biological engineer at the University of British Columbia. “We tested actual water from poultry feedlots and water streams, and in both cases, it worked quite well with 80% to over 90% removal efficiency.” The persistence of antibiotics in the environment has led to an alarming rise in bacterial antibiotic resistance in recent decades. “But there is no universal method to remove antibiotics from water easily and cost effectively,” he says.

Adsorbents like activated carbon, biochar, and zeolites are the most straightforward and low-cost option for removing antibiotics from wastewater. Regenerating the materials for reuse requires a lot of heat, though. Nanofiltration and reverse-osmosis membranes that use expensive nanostructured materials such as graphene, MXenes, and metal- and covalent-organic frameworks can physically trap antibiotics. But it’s difficult for water to flow through such nanomaterials, so energy is required to push water through them faster.

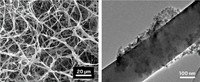

Rojas, Junling Guo of Sichuan University, and their colleagues decided to combine the two approaches by coating a membrane with a simple, biobased adsorbent material. They started with a highly porous polyamide membrane and installed it in the middle of a flow cylinder. They used this device to coat the membrane, purify water, and then regenerate the membrane for reuse.

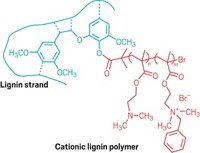

First, they pushed a solution of tannic acid and metal ions across the membrane to coat its pore surfaces. Tannic acid, which comes from plants and is used to dye garments and tan leather, is known to form complexes with metal ions and proteins. This prompted the team to try it as an adsorbent for antibiotics, which contain many of the same types of bonds and functional groups found in proteins, Guo says. They found through molecular dynamics simulations that antibiotics and tannic acid do interact through hydrogen bonding, electrostatic interactions, hydrophobic interactions, and π-π interactions.

To test the coated membrane’s ability to purify water, the researchers pushed a simulated wastewater mixture of 10 different antibiotics across the membrane through the tube-like device. The membrane removed over 80% of eight of the drugs. They also tested it with ciprofloxacin-laced wastewater from a poultry farm in China and found that the membrane removed over 98% of the antibiotic.

Finally, to regenerate the membrane, the researchers passed a mild acid solution through it to remove the tannic acid, which had adsorbed the antibiotics, before preparing it again with fresh tannic acid. They could reuse the membrane 10 times. Water flows through the new membrane much faster than filtration membranes reported so far, so it needs less than a quarter of the energy to pump water through the same volume of the membrane material.

Using adsorption instead of physical trapping allows the membrane to work quickly and grab many different molecules, says Yunkun Wang, an environmental engineer at the University of Science and Technology of China. “However, adsorption can be a double-edged sword,” with the need to rebuild the tannic acid coating for reuse, making it relatively more difficult in a practical setting, he says. Nonetheless, the low energy consumption and high removal efficiency for a range of antibiotics is a big advantage.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter