Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Glass Gets Tough with Alumina

by SARA LAJEUNESSE

August 16, 2004

| A version of this story appeared in

Volume 82, Issue 33

MATERIALS RESEARCH

New method makes hard, alumina-rich bulk glasses and glass ceramics possible

A new method for producing glass and glass ceramics that makes them more resistant to fractures could quell moving anxieties in the future. Anatoly Rosenflanz and coworkers at 3M Central Research Laboratory, St. Paul, Minn., have found a way to produce alumina-based glasses and glass ceramics that are harder and tougher than traditional silica-based glasses [Nature, 430, 761 (2004)].

Creating bulk glasses from pure molten alumina (Al2O3) has not been possible in the past because the cooling rate required to convert to a glassy form is extremely fast: up to 10 million K per second. One potential solution is to alloy alumina with other oxides such as calcium or rare-earth oxides. Yet even these alloys require very fast cooling rates, and they yield only tiny volumes of glasses.

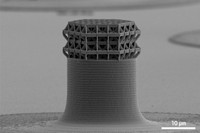

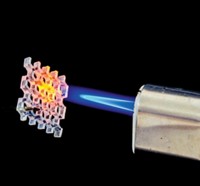

Using a flame-spray technique, Rosenflanz and coworkers were able to generate 140-µm-diameter glass beads containing 80% alumina from alumina alloyed with a variety of rare-earth oxides. This technique involves heating oxide powder in a high-temperature hydrogen-oxygen flame followed by rapid cooling.

Preparation of bulk glass, however, can occur only at certain temperatures--those between the glass-transition temperature (Tg) and the crystallization temperature (Tx)--the kinetic window. Previous studies have shown that a large kinetic window exists for alloys of alumina and rare-earth oxides. The 3M team sintered the glass beads at temperatures within this window to convert them into bulk glasses. X-ray diffraction and differential thermal analysis revealed that the bulk glass remained as amorphous and transparent as the flame-sprayed beads.

The researchers then proceeded to heat the alumina-rich bulk glass above Tx to produce nanoscale glass ceramics that are nearly twice as hard as the original bulk glass. This method of producing glass ceramics yields microstructures that are finer and more homogeneous than those produced using traditional methods. In addition, the glass ceramics have superior chemical, mechanical, and optical properties compared with silica-based glasses.

"This work combines some extraordinary properties of rare-earth aluminates in a novel way to produce an interesting new material," says Richard Weber, a scientist at Containerless Research, a materials research company in Evanston, Ill. "The products have many potential applications where toughness and strength are required," he says.

According to Paul F. McMillan, professor of chemistry at University College London and the Davy-Faraday Laboratory of the Royal Institution of Great Britain, applications include optical fibers, gas turbines, supports for catalytic reactor systems, and protective tiles for space probes.

And who knows? Maybe someday these methods will be used to produce items for everyday purposes. But for now, we'll have to stick with bubble wrap.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter