Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Waterproof Filter Paper

Polymerization technique yields superhydrophobic cellulose surfaces

by Michael Freemantle

August 23, 2006

In work aimed at developing superhydrophobic biofiber surfaces, polymer scientists in Sweden have shown that filter paper can be turned into a water-resistant, self-cleaning material. Water droplets roll off the surface of the paper, carrying dirt with them (Chem. Commun., 2006, 3594).

The research paper describes a facile way to transform a very hydrophilic substrate into an extremely hydrophobic one. "To the best of our knowledge, this is the first example of a superhydrophobic cellulose substrate," says professor of coating technology Eva Malmstr??m, who carried out the work with colleagues at the Royal Institute of Technology, in Stockholm.

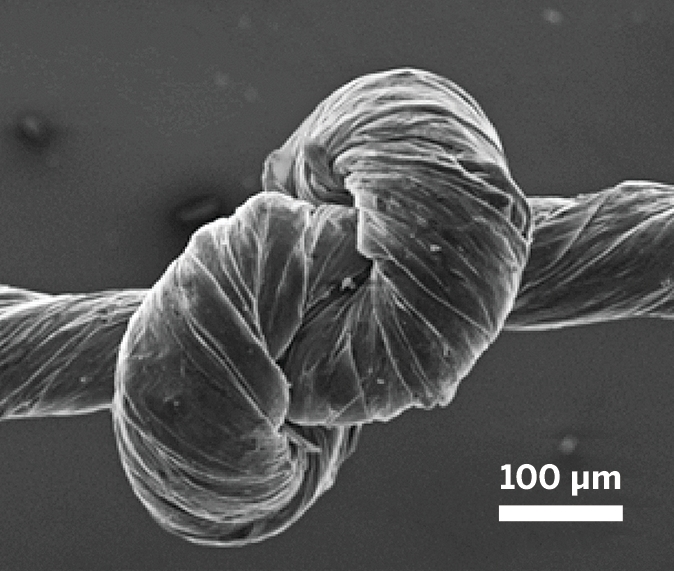

Cellulose is an abundant, inexpensive, biodegradable, renewable biopolymer that exhibits good mechanical properties. But it absorbs water. The creation of superhydrophobic, self-cleaning, cellulose-fiber-based materials could have potential applications in the textile industry, Malmström suggests.

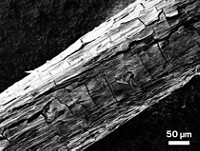

The Swedish scientists chose filter paper as their cellulose fiber substrate because of its high surface roughness. They used a process known as atom transfer radical polymerization to graft the fiber surfaces with a superhydrophobic polymer layer.

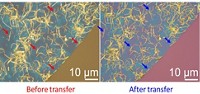

The team first immobilized a polymerization initiator, 2-bromoisobutyryl bromide, on the substrate. They then grafted glycidyl methacrylate, an epoxide monomer, onto the surface. After ring-opening of the epoxide groups, the resulting hydroxyl groups were reacted with pentadecafluorooctanoyl chloride. Fluorinated polymer brushes with a "graft-on-graft" architecture, as the authors call it, formed on the fiber surfaces.

"The process results in a polymer layer covalently attached to the surface that is sufficiently thick to bring about the superhydrophobic character," Malmström explains. "The approach is versatile and can be conducted on a variety of organic and inorganic substrates. It might also be possible to apply the technique to pattern thin papers or other biomass-based substrates and to use it for sensor applications."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter