Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Processing Milk Under Pressure

Low-temperature treatment keeps unsavory volatiles in check

by Sophie L. Rovner

November 14, 2006

High-pressure, low-temperature processing of milk could extend its shelf life without affecting flavor. At least that's the conclusion of some recent research.

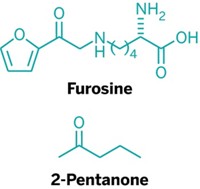

Most milk is heated at 72 °C for 15 seconds to rid it of microbes, providing it a shelf life of about 20 days under refrigeration. Ultra-high-temperature processing of milk at 135–150 °C for 3–5 seconds extends its shelf life to about six months at room temperature. But the technique can give the beverage an unpleasant cooked aroma derived from volatile sulfur compounds, aldehydes, and methyl ketones. Such compounds limit the milk's consumer appeal.

New technologies are being investigated for processing milk without compromising its flavor, including high-hydrostatic-pressure processing. Researchers have found that this method can be used to kill bacteria in milk at room temperature or above. Not a lot is known about flavor generation under high pressure, however.

Michael C. Qian and colleagues at Oregon State University set out to remedy that situation by studying the effect of pressures as high as 620 megapascals (about 90,000 psi) on milk flavor. Using methods such as solid-phase microextraction, gas chromatography, and pulsed-flame photometric detection, the researchers found that the impact of high-pressure processing on the volatile composition of milk is almost negligible at 25 °C but significant at 60 °C (J. Agric. Food. Chem. 2006, 54, 9184). The high-temperature treatment favors the formation of hexanal, heptanal, and nonanal, but the low-temperature treatment does not. The high-temperature treatment also produces more hydrogen sulfide.

These findings could help producers zero in on the best conditions for high-pressure processing of milk. The technique can extend the shelf life of refrigerated milk to at least 45 days, the researchers note.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter