Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Pick A Shape, Any Shape

Mask-based lithography method allows researchers to make arbitrary 3-D shapes

by Celia Henry Arnaud

February 7, 2007

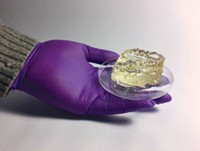

Using a mask-based approach, chemists at the University of Texas, Austin, can rapidly fabricate whatever shape they want through multiphoton photolithography. Creating a new object takes less than 10 minutes from the original conception to the completed object, thereby making rapid prototyping possible. Grad student Bryan Kaehr and associate professor Jason B. Shear fabricate micrometer-scale objects with shapes ranging from a common house fly to the state of Texas to a two-story "house" with tunnels for trapping bacteria (J. Am. Chem. Soc., DOI: 10.1021/ja068390y).

"Two-photon lithography is extremely powerful because it enables the formation of unusual three-dimensional micro- and nanostructures that would be difficult or impossible to fabricate using other methods," says John A. Rogers, a materials science professor at the University of Illinois, Urbana-Champaign. Rogers has also developed a mask-based approach to two-photon lithography that allows the formation of 3-D lattices in a single exposure step (Opt. Express 2006, 14, 2300). "Shear shows structure geometries that are different than and complementary to ours," he says. The two groups use different types of masks, Rogers says.

Shear's method requires more than a single exposure step, but it leads to a wider variety of shapes. Shear and Kaehr fabricate objects by focusing a laser beam through a confocal microscope to a tiny spot in a reagent solution, where the light promotes the cross-linking of proteins.

The researchers can direct the fabrication of objects with masks that they place in the path of the laser beam. They scan the laser beam in a raster pattern across the mask; cross-linking doesn't occur at the spots where the mask blocks the light. To create 3-D objects, they adjust the fine focus of the microscope and scan sequential planes.

Shear and Kaehr hope to use this technique to create 3-D replicas of biological materials. By making masks based on a series of confocal images and then stepping through the focal planes of the microscope for each new mask, they should be able to fabricate a replica of the original tissue. For instance, they hope to make replicas of extracellular matrix that they can use to grow neurons.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter