Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Steps In Tooth Enamel Formation Revealed

Matrix protein plays a critical role in crystallizing hydroxyapatite

by Jyllian Kemsley

April 2, 2008

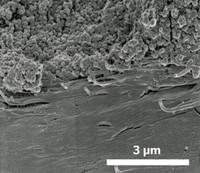

Tooth enamel, made from tightly packed hydroxyapatite nanorods, is one of the hardest and most durable materials produced biologically. Exactly how it is manufactured in the body is still a mystery.

Now, a group led by George H. Nancollas at the State University of New York, Buffalo, has identified specific stages of enamel crystallization and found that the matrix protein amelogenin promotes hydroxyapatite nucleation (J. Phys. Chem. C, DOI: 10.1021/jp077105+). A better understanding of how enamel forms could lead to improved dental materials.

Much past research into enamel crystallization has involved extreme conditions not found in physiological systems, including high temperatures and supersaturated concentrations of hydroxyapatite. Nancollas and colleagues took a different tack by lowering experimental concentrations to slow down crystallization and investigating hydroxyapatite nucleation at physiological pH and temperature.

The researchers found that the first step in their in vitro enamel production was the cooperative formation of composite nanospheres of nanocrystallite apatite and amelogenin. The composite nanoparticles then aggregated into nanorods that are about 50 nm in diameter and 250 nm long. The nanorods, in turn, further assembled to form organized, elongated crystals that began to resemble biological enamel.

Although the researchers caution against directly relating in vitro results to in vivo formation, the findings indicate that amelogenin may play a critical role in controlling structural growth of enamel crystals, they say.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter