Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Ibuprofen Goes With The Flow

Continuous-flow synthesis shows the way to safer, cheaper, and more efficient production of common painkiller

by Bethany Halford

October 19, 2009

| A version of this story appeared in

Volume 87, Issue 42

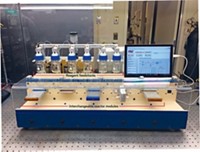

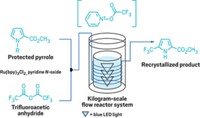

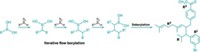

Using a three-step continuous-flow process, chemists at Florida State University have prepared the popular nonsteroidal anti-inflammatory drug ibuprofen (Angew. Chem. Int. Ed., DOI: 10.1002/anie.200903055). Such continuous-flow syntheses could lead to safer, cheaper, and more efficient pharmaceutical production, according to D. Tyler McQuade and Andrew R. Bogdan, who spearheaded the work. Their synthesis makes use of a simplified microreactor—a device in which reactions are carried out in microchannels or narrow-bore tubing. The system gives chemists precise control over heat transfer and mixing and also eliminates the need to purify any intermediates. To make ibuprofen, McQuade and Bogdan’s team had to design a reaction sequence in which all excess reagents and by-products were compatible with downstream reactions. Their scheme begins with a Friedel-Crafts acylation of isobutylbenzene, followed by a 1,2-aryl migration, and concludes with a saponification. With less than 500 cm of tubing and five syringe pumps, the chemists were able to produce crude ibuprofen at a rate of 9 mg/minute. They note that a continuous, high-throughput synthesis of the drug could be easily achieved by adding parallel reactors or by lengthening the channels combined with alternative pumping mechanisms.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter