Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Physical Chemistry

Metallic Aluminum Forms Tetrahedrons

Electron distribution maps provide a better explanation for some of bulk aluminum’s properties

by Jyllian N. Kemsley

March 28, 2011

| A version of this story appeared in

Volume 89, Issue 13

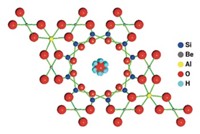

Atoms in aluminum metal are bound together in a tetrahedral geometry, a finding by researchers at Australia’s Monash University that better explains some of bulk aluminum’s properties (Science, DOI: 10.1126/science.1198543). The traditional view of a metal as an array of ions in a mobile sea of electrons works well to explain properties such as conductivity. But it doesn’t explain some mechanical qualities, such as why aluminum is more elastic in some directions than others, which would arise from directional bonding. In the sea of electron density, however, it is difficult to pick up localized electron distribution to identify bonds between atoms. Monash’s Philip N. H. Nakashima and colleagues used convergent-beam electron diffraction to map electron distribution in aluminum and observed that the atoms are bound together in a tetrahedral geometry, rather than in an octahedral or other fashion. The results agree with aluminum’s mechanical properties: The metal’s strongest axis passes through areas of highest bonding electron density within the tetrahedrons, whereas its weakest axis corresponds to holes in the electron density.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter