Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

OCI Bets On Polysilicon

Investment: South Korean firm will build world’s largest plant for the ubiquitous material

by Jean-François Tremblay

April 29, 2011

| A version of this story appeared in

Volume 89, Issue 18

South Korea’s OCI will spend nearly $1.7 billion to build what it claims will be the world’s largest single polysilicon plant. The company expects the 24,000-metric-ton-per-year facility to come on-line in 2013.

Polysilicon is used to create semiconductor wafers as well as high-efficiency photovoltaic cells. Both markets are healthy, although the photovoltaic industry, OCI’s target sector, is growing faster.

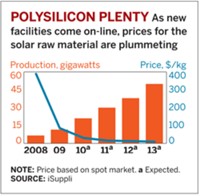

OCI acknowledges that it is investing at a time when the polysilicon market is becoming oversupplied. In South Korea and elsewhere, many producers are expanding capacity. “But by building larger, you get economies of scale,” an OCI spokeswoman tells C&EN. The firm’s polysilicon will be able to compete even if prices drop, she contends.

Polysilicon oversupply will begin in 2012, predicts Henning Wicht, a Munich-based principal analyst at IHS iSuppli, which provides market research services to the electronics and solar energy industries. The oversupply will develop because the leading polysilicon producers—OCI, Hemlock Semiconductor, Wacker Chemie, and GCL-Poly—are substantially expanding capacity at the same time that dwindling solar power subsidies in Europe are putting a damper on growth.

Yet OCI’s investment makes sense, Wicht adds, because all major polysilicon suppliers will compete on the basis of scale and costs. “The OCI expansion has to be seen in that context. Of many newcomers that have emerged since 2006, there is not one but OCI remaining,” Wicht says.

OCI says adding the new facility, in South Korea’s North Jeolla province, will make it the world’s largest producer of polysilicon. iSuppli projects that OCI will be the leading producer in 2013 and 2014 but that Hemlock will regain its leadership in 2015 when it completes facilities in Clarksville, Tenn.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter