Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Spinning Powder Into Yarn

Rolling up titanium dioxide powder in carbon nanotube sheets yields fabrics that maintain the powder’s properties

by Bethany Halford

January 10, 2011

| A version of this story appeared in

Volume 89, Issue 2

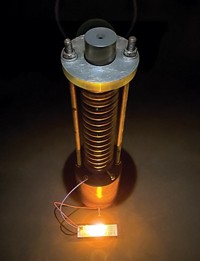

Using a scant portion of carbon nanotube sheets as support material, researchers at the University of Texas, Dallas, have devised a method to spin powders into yarn that maintains the properties of the original powder (Science, DOI: 10.1126/science.1195912). The technique, known as biscrolling, begins with a fine, weblike sheet of carbon nanotubes. Particulate or nanofiber powders are applied to the sheet via liquid-based methods, sputtering, or with an electrostatic powder-coating gun. Then stacks of the coated sheets are twisted into scrolls of yarn, with the particulate matter filling the scroll “galleries,” or spaces between the support material. The researchers, led by Ray H. Baughman, have used the technique to create yarns made of superconductors, lithium-ion battery materials, graphene ribbons, catalytic nanofibers for fuel cells, and titanium dioxide for photocatalysis. They also show that the yarns can be woven into fabric, tied into knots, and washed in a washing machine without losing their powdery particles. The researchers envision the technology could be used to make smart clothing, self-cleaning textiles, and solar cells.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter