Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Organic Solar Cells: Power From Plastic Photovoltaics

Polymer-based solar cells continue to show promise as low-cost electricity generators

by Mitch Jacoby

December 19, 2011

| A version of this story appeared in

Volume 89, Issue 51

COVER STORY

Organic Solar Cells: Power From Plastic Photovoltaics

“A decade ago we had vague concepts and power conversion efficiencies of just 1%. We have made tremendous progress since then.”

That perspective, from Nobel Laureate and University of California, Santa Barbara, chemistry professor Alan J. Heeger, sums up the status of organic photovoltaic (OPV) devices, which convert light to electricity. Scientists and engineers working in this field are out to develop polymer-based solar panels that are flexible and low cost, unlike traditional solar panels made from silicon and other inorganic materials.

The idea that photosensitive semiconducting organic polymers can be fashioned into OPV devices can be traced to Heeger’s Nobel Prize-winning work on electrically conductive polymers, which began in the late 1970s. By 2001, the field was buzzing with activity as researchers developed new members of this class of materials and studied their electrical performance. Even so, organic solar cells a decade ago were largely laboratory curiosities that produced electricity with very low efficiency—about 1%.

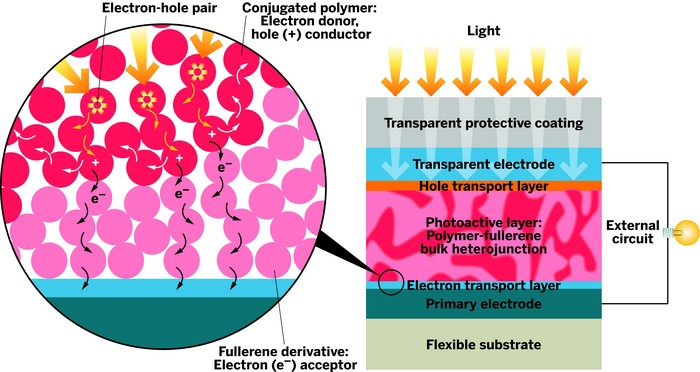

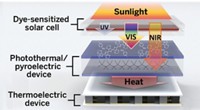

OPV performance has steadily improved since then, thanks to new types of photoactive materials and fine-tuning of the electronic and optical properties of the devices’ layers. Today’s best organic solar cells approach 10% efficiency. Along the way, scientists have deepened their understanding of how light impinging on a solar cell’s transparent outer layers stimulates excitations, forming electron-hole pairs in the inner photoactive layer. These charge couples split upon reaching an interface between nanosized domains of a conductive polymer (electron donor) and a material such as a fullerene (electron acceptor). The electrons and holes then travel to their respective electrodes, thereby generating current.

The past decade has witnessed the growth of companies, including Konarka Technologies, in Lowell, Mass., that produce large multicell OPV modules via roll-to-roll manufacturing processes. These modules are being incorporated into backpacks, handbags, and other irregularly shaped products to charge laptops, mobile phones, and other portable electronics while the owner is on the go. In addition to those retail consumer products, a broad selection of OPV modules is now being integrated into windows, skylights, and walls, turning building surfaces into inexpensive power generators.

One of the remaining challenges for OPVs, according to Russell A. Gaudiana, Konarka’s vice president for research, is overcoming the power-reducing electrical resistance caused by connecting multiple solar cells in series to form a power module. “We expect to raise the module efficiency by the end of 2011 to 5%,” Gaudiana says. “And we are working to develop new polymer families that will provide cell efficiencies of better than 10%.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter