Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Tuned-Up Rhodium Sharpens Butadiene Hydrogenation

Rhodium catalyst on a magnesium oxide support is partially deactivated by carbon monoxide to selectively produce butenes

by Stephen K. Ritter

September 10, 2012

| A version of this story appeared in

Volume 90, Issue 37

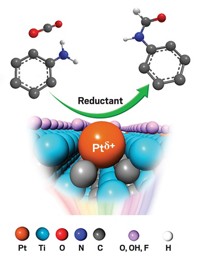

A fundamental study in tuning catalyst selectivity has solidified a new design strategy for making heterogeneous rhodium catalysts for butadiene hydrogenations (ACS Catal., DOI: 10.1021/cs300475c). The achievement by Dicle Yardimci, Pedro Serna, and Bruce C. Gates of the University of California, Davis, transforms rhodium, a catalyst metal traditionally considered unselective for this industrially important refinery reaction, into one that is highly selective. 1,3-Butadiene is a problematic by-product in the production of n-butenes by thermal cracking of petroleum—the butadiene must be removed to improve product quality and prevent catalyst deactivation. Chemists have been looking for highly selective catalysts to convert 1,3-butadiene to butenes under mild conditions without further converting the butenes to unwanted butane. Gates and coworkers prepared uniformly dispersed Rh(C2H4)2 on a magnesium oxide solid support. They then tuned the selectivity by treating the complexes with hydrogen to form dimers and displacing the ethylene ligands by exposing the material to carbon monoxide. The selective form of the catalyst is (CO)2RhRh(CO)2, which suppresses butane formation and forms n-butenes with 99% selectivity at butadiene conversions up to 97%. This catalytic activity matches that of the best gold catalysts reported for this reaction, the researchers note, but it occurs under much milder conditions of 40 °C and atmospheric pressure.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter