Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Gold Nanoparticles Improve Neural Electrodes

Nanomaterials: Tiny electrodes made of gold particles outperform best current ones in lab tests

by Corinna Wu

July 12, 2012

Many biomedical devices, such as pacemakers, cochlear implants, and prosthetics, require tiny electrodes that can interact with nerve tissue. For devices implanted inside the body, those electrodes have to last for years and be small enough to avoid causing scar tissue.

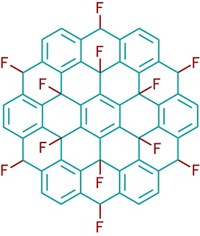

Now researchers have developed a new type of neural electrode made from gold nanoparticles (Nano Lett., DOI: 10.1021/nl3015632). The electrodes boast better electrical characteristics than ones made from carbon nanotubes, the current state-of-the-art material for neural interfaces.

Chemical engineer Nicholas Kotov of the University of Michigan, Ann Arbor, turned to gold nanoparticles because of gold’s high conductivity and biocompatibility. He knew that the metal had already found use in neural probes in the form of thin metallic rods.

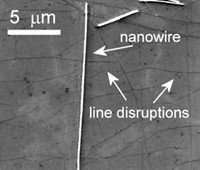

Unfortunately, manufacturers can’t make these rods small enough for implantable electrodes, Kotov says. To evade roving immune cells, electrodes must be smaller than 10 µm wide, he adds. If the cells attack electrodes, scar tissue starts to form, disrupting the contact between the device and nerve tissue. Researchers can make flat gold films at the right sizes, but these electrodes have high impedance, an electrical property related to resistance. Researchers want to use materials with low impedance because they allow electrons to pass more freely in the electrodes.

To make their nanoparticle-based electrodes, Kotov and his colleagues used layer-by-layer assembly, a technique that deposits nanometer-thick coatings of metal on surfaces. The method allowed them to control the thickness of the film and the location of the nanoparticles, which helps them fine-tune the electrode’s electrical and mechanical properties.

When the team tested the electrodes’ performance in an electrochemical circuit, they found that the impedance of the gold nanoparticle electrodes was one-fourth that of carbon nanotube-based ones. They also had about eight times higher charge storage capacity. Kotov was pleased with the result because electrodes with greater charge storage can better stimulate surrounding neural tissue. The test electrodes were 200 x 200 µm; Kotov plans to use the same technique to make smaller ones.

Robert Haddon, a chemist and materials scientist at the University of California, Riverside, applauds the team’s method for obtaining electrodes with “the right electrical characteristics you’d like to have in a very small-scale electrode.”

However, he points out that the layer-by-layer deposition method isn’t compatible with large-scale production of electrodes. Depositing the layers, building up to the final film thickness, takes time; by contrast, researchers can quickly make a carbon nanotube film of any thickness with a simple filtration method.

Haddon suggests a possible solution: coating carbon nanotubes with gold nanoparticles. The hybrid material, he says, could potentially “get the best of both worlds” in speed of production and electrical properties.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter