Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

A Cooler Route To Complex Crystals

Inorganic Chemistry: Quick and easy method crystallizes complex metal hydroxides at low temperatures

by Louisa Dalton

March 25, 2013

Synthetic inorganic chemists often turn to crystallization to create new inorganic materials for use in catalysis and energy production. These chemists often have to work hard to get all of their reactants into solution, relying on high temperatures and pressures. A new crystal growth method that works at far lower temperatures and pressures promises to make it easier to discover novel complex multielement materials (Inorg. Chem., DOI: 10.1021/ic302439b).

When inorganic chemists like Hans-Conrad zur Loye and his group at the University of South Carolina, Columbia, want to create new structures through crystallization, they first pick a solvent and dissolve into it everything they might want to see in the structure. Up to now, this dissolution step has required either temperatures between 600 and 1,200 °C or pressures above 625 atm. The chemists then slowly cool the mixture, allowing the crystals to grow unhurried.

Michael Chance, zur Loye’s graduate student, discovered a less troublesome process when he used a mixture that was half alkali metal hydroxide and half water to dissolve reactants. In the traditional, high-temperature methods, chemists use such hydroxides as solvents. In Chance’s method, the reactants dissolved at temperatures just above 200 °C and with pressures less than 1 atm. The mix, which zur Loye calls a hydroflux, can dissolve reactants at low temperatures because the hydroxide itself melts at much lower temperatures in the hydroflux than it does when alone.

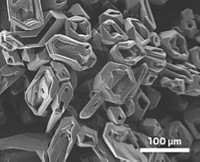

With the low temperature hydroflux, zur Loye’s post-doc, Daniel E. Bugaris, crystallized five complex, difficult-to-synthesize metal hydroxides: Sr6NaPd2(OH)17, Li2Pt(OH)6, Na2Pt(OH)6, Sr2Pt(OH)8, and Ba2Pt(OH)8. Hydroxides like these almost never form because of the high temperatures used in traditional crystallization methods, zur Loye says.

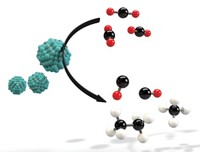

One reason chemists would want to synthesize the tricky hydroxides is that they offer an indirect way to make oxides often used in catalysis. Traditional syntheses for the oxides are notoriously cantankerous and require high temperatures, zur Loye says. His group showed that they could produce the oxide α-Na2PtO3 by gently heating the hydroxide Na2Pt(OH)6.

The group has also used their method to crystallize oxo-hydroxides, oxides, and oxide hydrates. They’ve worked with other metals, such as manganese and cobalt, and hope to next try ruthenium, iridium, and rhodium.

Maria Flytzani-Stephanopoulos of Tufts University, who works on metal catalysts, thinks the hydroxides are intriguing potential catalysts, because they are stable over a range of temperatures. She says the crystal growth method is so simple and requires such low temperatures that chemists will be able to play with it to make new materials.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter