Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

New Cathode Material For Lithium-Ion Batteries

Batteries: Material made of abundant elements could increase the capacity of rechargeable batteries

by Neil Savage

October 3, 2013

Between charges, an electric vehicle can travel only as far as its rechargeable lithium-ion battery allows it. And those batteries can only pack so much energy into a given volume. Making the batteries bigger would add weight to cars and be counterproductive. Now researchers have demonstrated a new battery cathode material that could potentially pack more charge into the same mass (Chem. Mater. 2013, DOI: 10.1021/cm402567e).

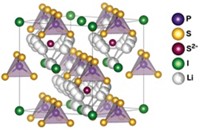

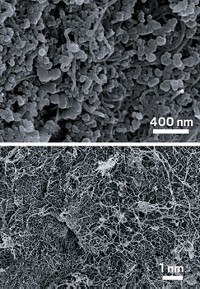

Peter G. Khalifah, a chemist at the State University of New York, Stony Brook, and Brookhaven National Laboratory, and his colleagues wanted to develop a cathode material that had good electrochemical properties and did not contain rare-earth elements, which are expensive and limited in supply. They started with an iron nitridophosphate, a compound of sodium, iron, phosphorous, oxygen, and nitrogen—all earth-abundant elements. They ground the material into a powder, mixed it with a powder of lithium bromide, and heated the mixture under a flow of nitrogen gas. During the heating, the lithium ions replaced the sodium ions. The researchers used the resulting material as a cathode in a battery and measured the material’s energy capacity as 125 mAh/g. Today’s lithium-ion batteries top out around 150 mAh/g.

Khalifah says this is just a first step in demonstrating this new material system for battery cathodes. Altering the structure of phosphorus groups in the material could produce a cathode material with a theoretical energy density upwards of 200 mAh/g, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter