Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Silk Fibers Grow Directly On Graphene

Materials Science: The strong, flexible, and conductive nanocomposite of silk and graphene could be used to make biosensors or scaffolds for tissue engineering

by Melissae Fellet

January 31, 2014

Researchers report a new biocompatible material that combines properties of natural and synthetic nanomaterials. The team grew silk nanofibers directly on graphene to produce a film that is flexible, strong, conductive, and can serve as a scaffold for growing cells (ACS Macro Lett. 2014, DOI: 10.1021/mz400639y). Experts think the work demonstrates how graphene might be used to direct the assembly of protein-based materials.

In 2012, Raffaele Mezzenga, at the Swiss Federal Institute of Technology, Zurich (ETH), and his colleagues reported a biosensor based on a material created from graphene and amyloid fibers (Nat. Nanotechnol. 2012, DOI: 10.1038/nnano.2012.62). The material combined the properties of each component: electrical conductivity from the graphene and biocompatibility from the amyloid fibrils. They used it to make sensors for humidity levels and enzyme activity.

The researchers thought they could improve the strength of the material by using silk fibers instead of amyloid fibers. But when they combined graphene with silk proteins, they found that the material formed differently than when they used preformed amyloid fibers. The previous material spontaneously formed as layers of graphene linked by amyloid fibers. With silk, the graphene sheets helped the proteins assemble into fibers.

To make the new nanocomposite, the researchers dissolved silkworm cocoons in water to get a solution of silk protein. They adjusted the pH of the solution to be above 10. Then the scientists added sheets of graphene oxide to the mixture along with a drop of hydrazine to reduce the graphene oxide to graphene. The researchers stirred the black suspension for six hours at 70 °C to produce the hybrid nanomaterial.

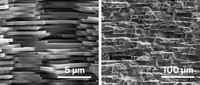

Atomic force microscopy images of the material in the suspension revealed layers of silk fibers completely covering the graphene sheets. The 3.5-nm-high silk fibers looked like a beaded necklace, which more closely resembles the structure of natural spider silk than reconstituted silkworm silk: The graphene had directed the silk proteins to form fibers in new way, Mezzenga says.

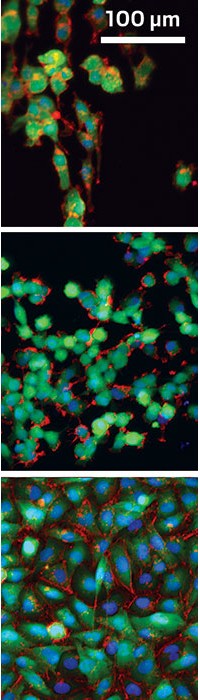

The researchers made the new material into large black sheets by filtering the suspension under vacuum. These sheets were 100 times more conductive and more than 10 times tougher than pure graphene oxide, yet they remained flexible enough to be tied into a knot. To test the material’s biocompatibility, the researchers grew human cervical cancer cells on the sheets. The cells grew to cover an area on the new material five times larger than on pure graphene.

Sang Ouk Kim, of the Korean Advanced Institute of Science & Technology, says this is interesting fundamental work showing that graphene can promote protein assembly much like inorganic crystals do in natural biocomposites, such as bone and tooth enamel.

Pierangelo Metrangolo, of the Polytechnic University of Milan, in Italy, says the work suggests graphene sheets could be a way to control the self-assembly of silk in the lab, which is not typically easy. However, he would like to see if the material can be made reproducibly on a large scale because the processing of graphene and of the new composite can be tricky.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter