Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Strong And Springy Materials Made In The Freezer

Materials: Versatile ice-templating method organizes glassy particles inside a polymer mesh to yield a variety of porous, elastic materials

by Prachi Patel

September 8, 2014

Researchers have developed a one-step freezing method to make porous inorganic materials that can spring back after being squeezed to 15% of their original size (Chem. Mater. 2014, DOI: 10.1021/cm502643a). These ultralight elastic materials could find use in tissue-engineering scaffolds, biomedical implants, and electronics.

Many strong, porous inorganic materials, such as silica aerogels and metal foams, currently find use in insulation, aircraft wings, and battery electrodes. But these lightweight materials are brittle. Compress them too much and they crack or crumble. Some scientists have crafted airy lattices of ceramics and metals that are slightly flexible. Unfortunately, these materials require etching with complex lithography or laser writing techniques.

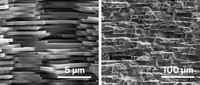

By contrast, the new springy materials are made using a simple 60-year-old process called ice-templating. Others have used the process to fabricate porous ceramic and metal structures by freezing colloidal suspensions. But in a novel twist, a team led by Guruswamy Kumaraswamy and Sayam Sen Gupta of the National Chemical Laboratory of India’s Council on Scientific & Industrial Research combined ice-templating with polymer cross-linking. This resulted in rigid particles dispersed in a three-dimensional web of organic polymer.

To make the new materials, the researchers start with their particles of choice dispersed in water. They next add an organic polymer along with a poly(ethylene glycol) cross-linker, and then start freezing the mixture. As ice crystals form, the particles move to the crystal boundaries, Kumaraswamy explains. The polymer forms a 10-nm-thick film around the particles and then gets cross-linked in the frozen state. These films create “remarkably flexible links between particles,” he says. Finally, the researchers thaw the mixture to get their porous elastic composite.

The freezing technique is versatile, Kumaraswamy says. Researchers could mix and match a wide range of different particles and polymers to tailor the material’s mechanical, electrical, and thermal properties. For example, the team made composites using 300-nm- and 1-µm-diameter silica particles in polyethyleneimine, as well as 300-nm-wide hydroxyapatite particles in gelatin. The hydroxyapatite and gelatin material was biocompatible: Mice showed no adverse effects two weeks after the material was implanted under their skin. The method should also be straightforward to scale up, the researchers say.

The researchers tested each material’s elasticity by squeezing it between two metal plates. No matter what its composition was, the material quickly sprung back after being squashed to 15% of its original size. Some even recovered, albeit more slowly, when compressed to 10% of their original size.

Julia R. Greer, a materials scientist at California Institute of Technology, says because the materials are porous and bounce back after being deformed, they could have a slew of biomedical applications, such as implantable medical devices and tissue scaffolds. “Any implantable biomedical device would be a lot more reliable if there was no concern that it would break inside the body.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter