Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Catalysis

Copper Clusters Convert Carbon Dioxide To Methanol

Catalysis: Four-atom copper fragments speed up greenhouse gas conversion without piling on the pressure

by Mark Peplow

July 13, 2015

With the help of the right catalyst, carbon dioxide emitted by fossil-fuel power stations could be used as a chemical feedstock, rather than contributing to greenhouse gas emissions. Researchers have now found that tiny clusters of copper atoms can generate methanol from CO2 at an unusually low pressure (J. Am. Chem. Soc. 2015, DOI: 10.1021/jacs.5b03668).

Copper is already used to catalyze industrial methanol production from syngas—a mixture of carbon monoxide, CO2, and hydrogen—at pressures of 10 to 100 atm and temperatures of a few hundred degrees C. But these conditions make the process energy-intensive and costly. “We wanted to use lower pressure to save energy,” says Larry A. Curtiss of Argonne National Laboratory.

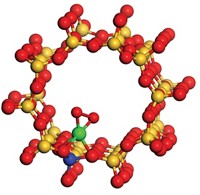

Curtiss—working with Peter Zapol, Stefan Vajda, and colleagues—calculated that copper clusters containing four atoms would offer higher catalytic activity than larger clusters or copper surfaces. The smaller clusters have more coordination sites available to bind reaction intermediates, offering a lower-energy reaction pathway.

The team peppered a thin film of alumina with Cu4+ clusters, and then monitored reactions over this catalyst in a gas stream containing 1% CO2, 3% H2, and 96% helium at an overall pressure of 1.25 atm. As they increased the temperature to 125 ºC, the H2 reduced the copper clusters to catalytically active Cu40. Methanol production peaked at 225 ºC, giving the highest reported activity for CO2 reduction to methanol at such a low CO2 partial pressure, a pressure around one-twentieth of that in work with previous catalysts.

Although promising, it remains to be seen whether this would be a chemically—or economically—viable way of utilizing CO2 waste from power plants. For now, Curtiss and his colleagues are looking for clusters that produce longer-chain hydrocarbons from CO2, potentially offering a renewable source of liquid fuels. Preliminary calculations suggest that a Cu20 cluster might be ideal, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter