Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

ACS Meeting News: Sturdy Silica Coatings Take Tough Stance Against Corrosion

by Matt Davenport

August 17, 2015

Engineers have long relied on polymer paints to slow metal corrosion, but these soft materials degrade in a matter of years and their upkeep is costly. Now, researchers have turned to inorganic chemistry to create long-lasting coatings that fight oxidation on multiple fronts.

Jason J. Benkoski of John Hopkins University’s Applied Physics Laboratory unveiled the composition of these coatings Sunday at the American Chemical Society national meeting in Boston in a session hosted by the Division of Polymeric Materials: Science & Engineering.

The coatings are water based—allowing the team to spray them onto metals—but their inorganic contents, including silica, cerium, and zinc oxide, dry to form insoluble materials, creating a corrosion fighting coat that’s stable in water.

The silica provides a durable foundation and cerium is a well-known oxidation inhibitor.

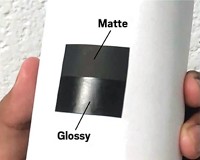

But the coating also fights heat, an important, but frequently overlooked contributor to corrosion, Benkoski tells C&EN. Ships and other metal vehicles often bear polymer paints that warm up in sunlight, accelerating both their own degradation and the metal’s corrosion. (Benkoski’s work is supported, in part, by the U.S. Office of Naval Research.)

So the team added zinc oxide to its coatings to reflect warming energy in the sun’s rays. Coupled with silica’s ability to emit thermal energy, the coatings passively cool themselves, Benkoski says. Coated surfaces didn’t warm much even when the team added perylene black pigment, which typically absorbs the sun’s heat.

“The optical properties giving the passive cooling are very exciting,” says Jeffrey Wilbur, a research scientist with the Dow Chemical Company. But he adds that the inorganic coatings do have some challenges to overcome, including the brittleness of silica.

The researchers are working to build silicone into the paint to make it more flexible. The team is also experimenting with waxy siloxane microcapsules to bestow self-healing capabilities to their coatings.

“We want to make them last forever,” Benkoski says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter