Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

ACS Meeting News: Green carboxylation could convert biomass to plastic

by Stu Borman

March 16, 2016

Inspired by how plants transform carbon dioxide to carbohydrates in photosynthesis, researchers have developed an environmentally friendly reaction that adds the greenhouse gas to organic compounds, including biomass-derived molecules.

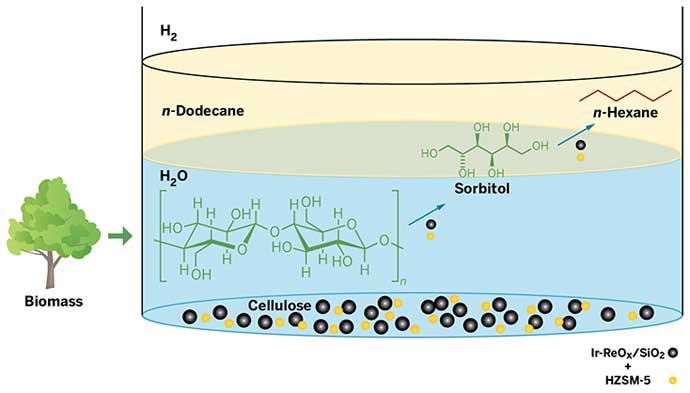

This week at the American Chemical Society national meeting in San Diego, the team described how they used the carboxylation reaction to synthesize a monomer that could help make a substitute for polyethylene terephthalate (PET), the soda-bottle polymer that is one of the world’s largest volume plastics. They think the chemistry could open a new route for converting biomass into polymeric materials and fuels.

CO2 reacting with carbanions and other nucleophilic carbon centers to form carboxylates isn’t a new concept. But generating nucleophiles generally requires reagents such as highly reducing metals or strong organic bases that are energy-intensive to make and difficult to recycle. “These requirements negate the environmental benefit of using CO2 as a substrate and limit the chemistry to low-volume targets,” noted Matthew W. Kanan of Stanford University and coworkers in a recent paper (Nature 2016, DOI: 10.1038/nature17185).

In the new chemistry, Kanan and his team use carbonate to deprotonate weakly acidic C–H bonds in organic substrates. The chemists facilitate this deprotonation by running the reaction in intermediate-temperature molten salts containing cesium or potassium ions, which stabilize the deprotonated form of the substrate. The resulting nucleophilic carbon then reacts readily with CO2 to form carboxylates. The carbonate, which is consumed in the carboxylation, can be regenerated easily in a separate step.

At a symposium in the Division of Energy & Fuels, Kanan’s graduate student Aanindeeta Banerjee described how the team used this method to carboxylate 2-furoic acid to make furan-2,5-dicarboxylic acid (FDCA). This compound can polymerize with ethylene glycol to form the possible PET substitute polyethylene furandicarboxylate (PEF). Unlike PET’s monomers, which are derived from petroleum, 2-furoic acid can be made from agricultural waste–corn- or sawdust-derived lignocellulose.

Amsterdam-based Avantium is currently developing a commercial process to convert FDCA to PEF. The company makes FDCA from plant-based sugars. Making it instead from inedible biomass would skip difficult dehydration processes, leading to a more efficient process with lower CO2 emissions, Kanan says.

“Once scaled up, the new route might be less wasteful—needing fewer raw materials and less energy—than the conventional industrial synthesis of FDCA,” says chemical and petroleum engineer Eric J. Beckman of the University of Pittsburgh in a commentary that accompanies the recent paper. However, “a comparison of the life-cycle impacts of the two routes will need to be performed to ensure that it is truly more sustainable.”

Liang-Nian He of Nankai University, Tianjin, China, an expert on chemical fixation of CO2, comments that this “inorganic carbonate-promoted C–H carboxylation opens a new way to convert inedible biomass and CO2 into valuable chemicals and materials.” But He points out that the process still has additional energy costs associated with forming molten salts.

Kanan says his group is working on scaling up the reaction to try to commercialize it. He thinks that the carboxylation reaction could also be used to make fine chemicals and specialty chemicals in a low carbon-footprint way.

Other Related Stories:

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter