Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Graphene opens up new applications for microscale resonators

Operation at high temperatures and broad tunability could bring microelectromechanical resonators to space and beyond

by Dexter Johnson, special to C&EN

March 9, 2018

A range of sensing and communications technologies, such as satellites, already rely on tiny devices called resonators—also known as vibrating microelectromechanical and nanoelectromechanical systems (MEMS/NEMS). But engineers have faced limits in the temperatures these tiny components can withstand and the range of frequencies that they can pick up. Now scientists at Case Western Reserve University have constructed resonators out of a single layer of graphene that can withstand high temperatures and operate across a broad range of frequencies (Nano Lett. 2018, DOI: 10.1021/acs.nanolett.7b04685).

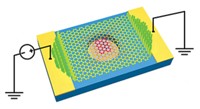

Today MEMS/NEMS resonators are usually made out of silicon, but a few years back researchers started to make them out of graphene because of the material’s superior physical properties. Chief among these are its high conductivity, mechanical flexibility, and light weight. These atomically thin, two-dimensional resonators operate like the skin of a drum, vibrating at certain frequencies. When employed as sensors, these frequencies shift when struck by stimuli, such as molecules or photons. By analyzing those frequency shifts, it becomes possible to know the quantity and nature of the stimuli.

Although previous research groups had fashioned these MEMS/NEMS resonators out of graphene, they had not made them to operate at high temperatures. So Philip Feng, a professor of electrical engineering & computer science at Case Western, and his colleagues decided to focus on a particular property unique to graphene: its negative thermal expansion coefficient. This means that when graphene heats up, it shrinks, whereas silicon expands when heated, as most other crystals do.

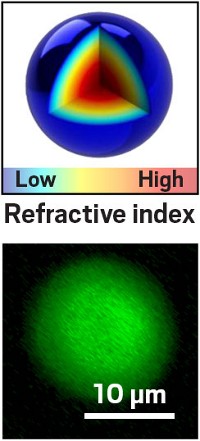

To build their new resonators, Feng and colleagues carved circular cavities 3-5 µm in diameter out of a layer of silicon oxide on silicon chips, and then placed flakes of graphene across the openings to create these graphene drumheads. The researchers were able to fashion a device that would shrink and increase its tension when in different temperature environments, thus changing its frequencies. The new devices can function at temperatures that exceed 900 °C.

In many resonators, the resonance frequency is tuned by applying an electrical signal, usually a voltage. “What’s new here is the unprecedentedly broad tuning range,” Feng says. “Conventionally, one needs to employ different resonators to cover different ranges of frequency, such as the drums with varying sizes in an orchestra. The broad tuning range made available by graphene’s shrinking at higher temperatures means one device can cover a much wider range than before.”

This latest graphene version could open up new applications for resonators, says Anirudha Sumant, staff scientist at the Center for Nanoscale Materials at Argonne National Laboratory. Most work on MEMS/NEMS resonators has been done either at room temperature or at low temperature, despite the high demand for resonators that can operate in harsh environments or in space applications, he says. “In that context, this is a significant development.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter