Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

3-D Printing

3-D printing complex objects in a flash

Technique uses photoswitchable molecules for fast, precise polymerization

by Bethany Halford

December 24, 2020

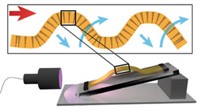

Taking advantage of molecules that switch states when exposed to particular wavelengths of light, researchers have developed a 3-D printing method that can make precise objects in a matter of minutes. The technique, developed by Stefan Hecht of RWTH Aachen University, Martin Regehly of Brandenburg University of Applied Sciences, and colleagues at the Berlin-based start-up xolo, is called xolography because it uses the crossing of light beams to create whole objects (holo is the prefix for whole and x signifies criss-crossing). The technique offers a way to make multicomponent objects with fine details, such as flow cells with blades that spin on an axle for transporting and mixing reagents. Xolo plans to commercialize the xolographic printer.

Xolography is a variant of volumetric 3-D printing. Instead of laying material down layer-by-layer with nozzles, like most 3-D printing, volumetric methods use light to selectively polymerize portions of a container of viscous liquid and wash away the rest, resulting in a solid object. Interest is growing in volumetric 3-D printing to make objects with fine features. In contrast to other volumetric approaches, Hecht and Regehly’s xolography technique is both fast and doesn’t require the expensive equipment that some other volumetric techniques do.

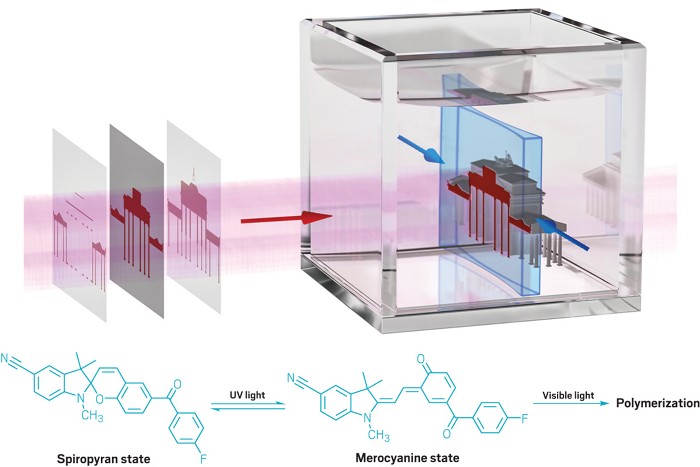

The new method relies on a photoswitchable molecule, which changes its structure when exposed to light. The researchers mix a photoswitchable spiropyran into the monomer-containing viscous liquid in their setup. When the researchers shine UV light on the material, the spiropyran molecules in the beam’s path switch to a merocyanine state. If the researchers then expose the molecules in the merocyanine state to visible light, the compounds initiate a polymerization reaction, hardening the viscous liquid. If merocyanine molecules don’t encounter visible light, they quickly switch back to the spiropyran state and no polymerization occurs. By shining the visible light from the perpendicular direction to the UV beam, the researchers can harden the liquid just at the point of intersection, giving precise control (Nature 2020, DOI: 10.1038/s41586-020-3029-7).

Hecht, who has studied photoswitchable molecules for 15 years, says his group tried many molecules before finding the right one for xolography. He notes that for data storage, most switchable molecules have to be slow at moving back to their original state. But for this application, they wanted the molecules to switch back quickly so they wouldn’t initiate polymerization in unwanted areas. This fast switching also speeds up the printing process.

The researchers report making structures with micrometer precision, but Vittorio Saggiomo, who studies 3-D printing at Wageningen University and Research, says the group should be able to achieve even finer features in the objects they create by using certain fluorescent microscopy set-ups. The challenge, he says, will be creating objects that are larger than 10 cm because of light diffraction, scattering, and absorption.

“Xolography represents an elegant leap forward in 3-D printing technology by embracing the inherent interdisciplinarity of this arena, which brings together, among other things, innovative synthetic materials and optical engineering,” says University of Texas at Austin’s Zachariah Page, a 3-D printing expert, in an email. “It is a truly exciting advance in manufacturing that enables an unmatched combination of speed and resolution, while further demonstrating the power of light.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter