Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biomaterials

Mussel adhesives rely on a pinch of vanadium

Mussels slowly sprinkle metal ions into sticky protein fluid to make tough glues that cure underwater

by Prachi Patel, special to C&EN

October 8, 2021

Scientists have reported surprising insights into how mussels make the tough, underwater-curing glue that anchors them to wet rocks and piers. The bivalves’ secret is vanadium. Mussels slowly mix that rare metal, along with iron, into their adhesive proteins in microscopic channels right before they secrete them (Science 2021, DOI: 10.1126/science.abi9702).

Mussels are known to accumulate heavy metals. But this is the first study to show that they are actively soaking up trace bits of vanadium from water and using it to make their adhesive.

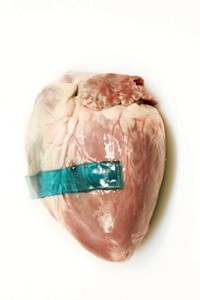

“It’s like a two-part epoxy, except in a micro-scale process,” says Matthew Harrington, a chemist at McGill University, referring to the industrial-strength glues composed of a resin and a curing agent that are mixed right before application and cure as the two components react. The mussel-glue insight could be important for making medical adhesives that can be applied to wet tissues and other surfaces, which he says, “most man-made adhesives are pretty terrible at.”

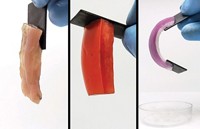

To stick to underwater surfaces, mussels secrete proteins that cross-link with each other and with rock surfaces via various chemical and physical interactions. Researchers have made synthetic polymer versions that mimic those proteins.

But mussel adhesives also contain metals bound with the proteins, which help cure the glue to make it stronger and harder. Until now, researchers thought mussels used only iron, the most abundant metal in seawater. And no one understood how the metal gets introduced--whether it came straight from seawater or if the animal somehow added it.

Harrington and his team used a battery of microscopy, spectroscopy, and tomography techniques to study the mussel’s glue-secreting organ. They found a complex network of microscopic channels in the organ ducts. Around the channels were clusters of spherical sacs containing proteins in solution. More sensitive fluorescence and spectroscopy showed a smaller number of tinier particles carrying vanadium and iron ions.

When the mussel releases the protein sacs and metal particles into the channels, the sacs break open, likely because of a change in pH or other chemical conditions. The small protein globs coalesce to form a dense fluid mass that cannot mix in water and the metal particles slowly release metal ions into the fluid as it moves down the channel and out of the animal. “They have a slow-release mechanism, kind of like a bath bomb,” says Harrington.

He and his team recently reported that vanadium bonds with the proteins twice as strongly as does iron, adding strength to the adhesive (Chem. Mater. 2021, DOI: 10.1021/acs.chemmater.1c02063). Previous artificial glues have used iron, but the new information suggests that adding vanadium instead and mimicking the mussels’ slow mixing via a microfluidic processing technique could improve synthetic adhesives’ properties by creating a hierarchically porous structure similar to what is found in the natural glue. “It’s not just about the chemicals, it’s how to copy nature’s fabrication method,” Harrington says.

Jonathan Wilker, a chemist at Purdue University who was not involved in the work, says this study “is definitely exciting.” Researchers are trying to make tough adhesives that can work in water, but their model systems are quite simple when compared to the intricate ways that mussels make their glues. “So we are still looking to, and learning from, how biology makes materials. These latest views on bioadhesive production are likely to influence where we go next.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter