Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Polymers

A synthetic polymer can bust biofilms like barnacles do

The polyester mimics barnacle secretions that clean surfaces

by Carolyn Wilke, special to C&EN

September 13, 2024

A new polymer removes biofilms—mats of microbes and their exuded substances—by mimicking a fluid oozed by barnacles (J. Am. Chem. Soc. 2024, DOI: 10.1021/jacs.4c09311). The material could provide a new strategy for cleaning the places where bacteria build up on medical or industrial equipment.

Before establishing a life on the rocks, barnacles clean their settling spot. “Mr. Clean is a barnacle,” says Dan Rittschof, a marine biologist at Duke University who wasn’t part of the new work. “We know that barnacles hate bacteria.” When juvenile barnacles are settling, part of their cleaning process involves exuding a fluid that is rich in lipids and phenolic compounds and removes biofilms.

Biofilms allow bacteria to cling to surfaces, such as those of medical devices or parts of the body, and can make for difficult-to-treat infections. Many researchers try to kill the bacteria to get rid of the biofilm, according to study coauthor Abraham Joy, a bioengineer at Northeastern University. “Oftentimes it doesn’t work because the bacteria are dormant inside the biofilm,” he says. Antibiotic efficacy often depends on the microbes having an active metabolism.

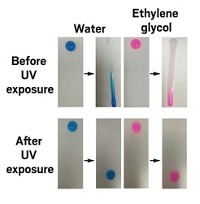

Amal Narayanan, a biomaterials scientist at the University of Florida, noticed that a polymer he had worked on with Joy could flow underwater like the surfactant that barnacles produce. The two materials also have similar phase separation behavior in water. That led the researchers to wonder whether their polymer—a polyester they had created to encapsulate and deliver proteins—might be similarly effective at clearing biofilms. When it turned out to be, Narayanan was shocked. “There’s no reason for it to work from a rational design point,” he says.

The researchers grew biofilms of the pathogen Pseudomonas aeruginosa in a glass channel underwater. They added their polymer to one end of the channel and tilted it. The polymer flowed through slowly and removed 99% of the biofilm as it slid along. But the liquid’s biofilm clearing power wasn’t just due to its thickness; other viscous polymers that were even more resistant to flowing failed to clear the biofilm. Additional experiments revealed that the polyester weakens the biofilm interaction with the glass surface, but it’s not yet clear what’s happening at the molecular level, Narayanan says.

The team also tested its polyester against biofilms of Klebsiella pneumoniae, Staphylococcus aureus, and Escherichia coli—other microbes that can cause infections in people. The polymer didn’t fare as well against these: it removed around 70% of the K. pneumoniae biofilm and didn’t even make a dent in the other biofilms. But Joy says the team may be able to target the approach for other microbes by tweaking the physical, chemical, and mechanical properties of the fluid.

“It’s a great study,” says Tagbo H. R. Niepa, a bioengineer at Carnegie Mellon University who wasn’t involved with the work. The chemical’s design could allow for cleaning of pipes, tubes, and surfaces. “You can think about a way of cleaning a catheter, for instance, that is fully infected with bacteria,” he says. But he adds that the approach should be tested in animal models to see what happens to the bacteria and biofilm that are removed.

The polymer was designed to have low toxicity, Joy says. And it could be delivered with an antimicrobial to kill bacteria that are released by displacing the biofilm. Depending on how costs and benefits of the new polymer stack up against current cleaning methods, the material may also be useful for cleaning industrial or fuel lines.

The new material could take further cues from barnacles. The marine creatures also secrete enzymes that break the gluey substance that holds bacteria on surfaces and send out a blast of unstable molecules called reactive oxygen species to kill bacteria, Rittschof says. The researchers might consider adding glue-cutting enzymes and molecules that generate reactive oxygen species, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter