Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Outside-the-box Approach to Biaryls

By not using a Suzuki coupling, seasoned process chemist dramatically reduces cost of synthesis

by A. MAUREEN ROUHI, C&EN WASHINGTON

September 6, 2004

| A version of this story appeared in

Volume 82, Issue 36

COVER STORY

OUTSIDE-THE-BOX APPROACH TO BIARYLS

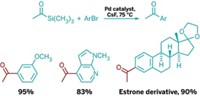

Suzuki couplings--the palladium-catalyzed joining of two aryl groups from one aryl halide and one arylboronic acid--are popular because of how easily they form the biaryl structure. But if the two reactants are expensive, a coupling might not be commercially viable.

Faced with such a situation in the synthesis of a biaryl-containing drug candidate, Atul S. Kotnis, a senior researcher at Bristol-Myers Squibb's process R&D center in New Brunswick, N.J., discarded the obvious solution and reached back to chemistry he had practiced years before. By doing so, he reduced the cost of materials by two orders of magnitude--a feat that earned him a BMS award for innovation in 2002.

The target was the drug candidate denoted BMS-30943, which the company was developing in the late 1990s for treating diabetes. For maximum efficacy, the drug would have had to be given in high doses, requiring large amounts of active ingredient. If the active ingredient were too expensive to make, the drug would be prohibitively costly.

The biaryl in the molecule is an obvious focus of construction by Suzuki coupling. However, the two coupling partners together cost $8,000 per kg: $4,500 per kg for the aryl halide and $3,500 per kg for the arylboronic acid. Add to this the cost of the palladium catalyst and other processing costs, and the price becomes untenable. "We would never be able to sell the drug," Kotnis says. "It would be too costly."

The problem was outsourced; various chemistries were tried. None was satisfactory. What eventually worked was chemistry that Kotnis had developed in 1988 to prepare a biaryl from a cyclohexenone-substituted benzene ring. Cyclohexenones aromatize easily, Kotnis knew from his postdoctoral work in natural product synthesis. When heated with iodine and methanol, they readily form methyl aryl ethers.

THE KEY STEP then is attaching a cyclohexenone to a benzene ring. Through lithium chemistry, the halogen on the pyrazole-substituted aryl bromide (or iodide) can be replaced with a cyclohexenone. Aromatization via iodine and methanol, however, produces a methoxy group on the benzene ring that would have to be converted to a hydroxyl group to reach the desired final product. To get directly to the hydroxyl group, Kotnis switched to a different reagent--pyridinium tribromide. At this point, Kotnis has in effect replaced the arylboronic acid partner of Suzuki coupling with a cyclohexenone and pyridinium tribromide, each of which costs less than $100 per kg. In addition, no palladium catalyst is involved, and all costs related to metal use are eliminated.

Further savings could be realized if the lithium chemistry could be achieved with the pyrazole-substituted aryl chloride. That reaction yielded a product with a mass that is 34 units higher than expected; that is, the product retains the chlorine of the aryl chloride. Studies showed that the cyclohexenone was not replacing the chloride but was adding to the benzene ring at a position activated by the pyrazole. Fortuitously, that position is precisely where the cyclohexenone needs to be.

The results suggested that addition of cyclohexenone can proceed without a halogen on the pyrazole-substituted benzene ring, and indeed it does.

The final accounting shows the following costs per kilogram of starting materials: about $500 for the nonhalogenated pyrazole-substituted aryl, about $80 for the cyclohexenone, and about $80 for the pyridinium tribromide. "What was $8,000 per kg has now become less than $800 per kg," Kotnis says.

"Most people see a biaryl and think of it as a biaryl. I see it as a substituted benzene," Kotnis says. "I will always consider Suzuki coupling in constructing a biaryl, but I will always keep in mind that there's another way of looking at it."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter