Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Sticky Feat

Reusable elastomer adhesive features liquid-filled microchannels resembling those in the feet of frogs and crickets.

by Rachel Petkewich

October 15, 2007

| A version of this story appeared in

Volume 85, Issue 42

Conventional adhesives such as packing tape can't be reused nearly as many times as tree frog feet. Embedding an elastomer with liquid-filled microchannels that resemble those on tree frog feet, however, creates a strong, reusable adhesive, according to a new study (Science 2007, 318, 203.)

"In essence, we are trying to mimic bioadhesives on the feet of many insects and vertebrates," says author Animangsu Ghatak of the Indian Institute of Technology, Kanpur.

Man-made adhesives (see page 39) crack when they are peeled off of a surface. The cracking mechanism allows release but also leads to loss of stickiness. To stop cracks from spreading during peeling, researchers have had some success in micropatterning the surface of adhesives.

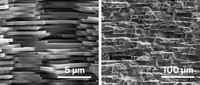

Ghatak and his colleagues created their adhesive with inspiration from fluid-containing vessels found in animals such as tree frogs and bush crickets. The scientists buried channels filled with silicone oil in the bulk and subsurface of a polymethylsiloxane elastomer. The deep channels act as a barrier to crack propagation and increase adhesion by a factor of 30. By adding a separate layer of oil-filled channels at the subsurface, the team created an adhesive that peels off surfaces easily. The researchers currently are examining how the geometry of channels affects adhesion.

The work is "innovative and provocative," though there may be challenges for manufacturing large quantities at low cost, says Phillip B. Messersmith, a professor of biomedical engineering and materials science at Northwestern University.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter