Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Need a Bone Graft? Print One Out

Ink-jet printer used to fabricate synthetic bone grafts

by Sophie L. Rovner

March 8, 2007

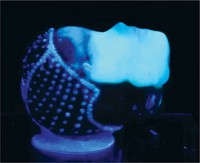

How's this for an unusual application for an ink-jet printer: Jake E. Barralet of McGill University, in Montreal, and colleagues have adapted a printer to produce synthetic, three-dimensional structures to make bone grafts (Adv. Mater., DOI: 10.1002/adma.200601370). Tests indicate that such porous, tailor-made structures could one day be implanted into patients to serve as biodegradable scaffolds for regrowing missing or damaged bone.

The printing technique precisely controls the size and geometry of the pores that riddle the scaffold to promote optimal bone growth. Instead of ink, the printer sprays out phosphoric acid in a defined pattern onto a bed of calcium phosphate powder on a movable platform. The powder forms cement at the spots that are wet with acid. The printer then drops the platform slightly, lays down another layer of calcium phosphate powder, and applies more acid.

Each 100-µm-thick layer takes about 10 seconds to print. The process repeats until the desired 3-D object is finished, at which point unreacted powder is removed with compressed air.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter