Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Printing with living inks

Bacteria-laden hydrogels with functional properties can be used to make structures for bioremediation and biomedical applications

by Celia Henry Arnaud

December 4, 2017

| A version of this story appeared in

Volume 95, Issue 48

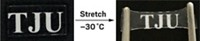

Researchers have used functional living inks, which they call Flinks, containing bacteria with useful reactive chemical properties for three-dimensional printing. André R. Studart, Patrick A. Rühs, Manuel Schaffner, and coworkers at ETH Zurich embedded the functional bacteria in hydrogels that can be used in 3-D printers to make a variety of structures for various applications (Sci. Adv. 2017, DOI: 10.1126/sciadv.aao6804). The hydrogel consists of hyaluronic acid, κ-carrageenan, and fumed silica at a 1:1:1 ratio. Increasing the weight percent of those components while maintaining the same ratio allows the researchers to adjust the viscosity and elasticity of the hydrogel. After chemically replacing the hyaluronic acid with glycidyl methacrylate hyaluronic acid after the printing step, the team used ultraviolet light to cross-link the hydrogel to form self-supporting structures. The researchers used a Flink loaded with Pseudomonas putida to make devices that can degrade phenols for bioremediation applications. They demonstrated potential biomedical applications using a Flink embedded with Acetobacter xylinum, a bacterium that produces cellulose. Bacterial cellulose is being developed as a material for skin repair and as a tissue envelope for organ transplantation. The researchers showed that they can controllably use the ink to make complex shapes by printing a scaffold in the shape of a miniature T-shirt and by depositing a film on a doll’s face as a model for a human face. In both cases, the bacteria produced a cellulosic biofilm.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter