Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Iodinated Polymers Visible To X-Rays

May 26, 2008

| A version of this story appeared in

Volume 86, Issue 21

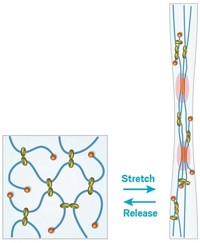

A new class of iodinated polymers may provide a way to monitor medical implants and drug delivery devices in the body. The iodine in these polymers makes them opaque to X-rays (radiopaque) and thereby visible in X-ray images. Previous attempts to make radiopaque polymers have involved incorporating iodine into nondegradable or slowly degrading polymers. Kathryn E. Uhrich and coworkers at Rutgers University, Piscataway, N.J., report radiopaque salicylate-based poly(anhydride-esters) that have iodine atoms incorporated into the backbone (Biomacromolecules, DOI: 10.1021/bm8000759). The polymers, which are fully biodegradable, demonstrate that it is "possible to combine iodine-based radiopacity with controlled biodegradation," comments Leo H. Koole, a professor of biomaterials science at the University of Maastricht, in the Netherlands. The Rutgers researchers compared two methods to make the polymers. The melt-condensation polymerization method formed stiffer polymers with higher molecular weights and higher radiopacity than did the low-temperature solution-based polymerization method. The radiopacity depended on the number of iodine atoms in the polymer. Polymers made by either method were biocompatible with mouse fibroblast cells at low polymer concentrations.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter