Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

A Pinch Of Salt Softens Hydrogel

A “saloplastic” polymer electrolyte complex can be reversibly softened up and processed as a biomaterial by simply adding table salt

by Stephen K. Ritter

November 9, 2009

| A version of this story appeared in

Volume 87, Issue 45

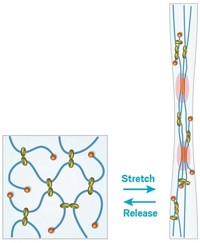

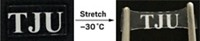

A new type of hydrogel made from a polymer electrolyte complex can be softened and processed into a biomaterial with mechanical properties suitable for medical implants simply by adding table salt to disrupt the ionic cross-links (Biomacromolecules, DOI: 10.1021/bm900373c). Claudine H. Porcel and Joseph B. Schlenoff of Florida State University developed combinations of cationic poly(diallyldimethyl ammonium) and anionic poly(styrene sulfonate) and found that ultracentrifuging the PDADMA/PSS materials with a concentrated sodium chloride solution forces salt into the complex where it breaks up some of the ion pairs that hold the polymer chains together. The partially liberated chains become much more mobile, similar to using heat to soften up a thermoplastic, Schlenoff says. This novel “saloplasticity” is reversible by adding water to dilute the salt. The hydrogel has micropores filled with extra polyanion, similar to the porous structure of cartilage that contains negatively charged proteoglycans. The extra polymer generates osmotic pressure to swell the hydrogel, making it elastic like a springy shock absorber. The team found one polymer combination that has properties similar to intervertebral discs—a type of cartilage made from a natural cross-linked hydrogel—and potentially could be used to make artificial replacements.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter