Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Refined Path From Biomass To Biofuel

Flow-reactor system converts γ-valerolactone into ready-to-use gasoline and jet fuel

by Stephen K. Ritter

March 1, 2010

| A version of this story appeared in

Volume 88, Issue 9

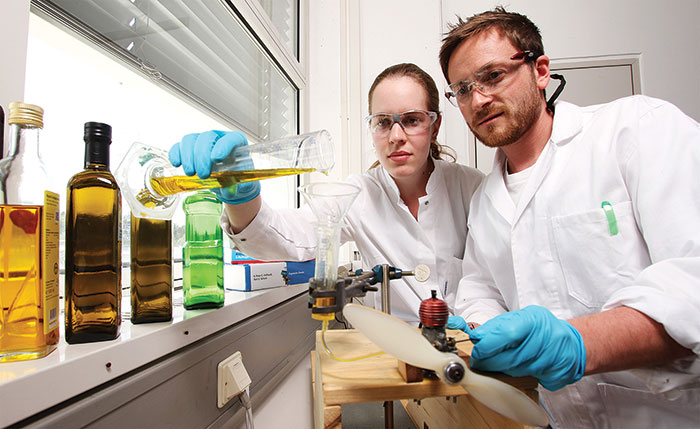

The challenge of economically converting lignocelluosic biomass into transportation fuels is to develop efficient chemistry that minimizes processing. In a bid to meet that challenge, Jesse Q. Bond, James A. Dumesic, and coworkers at the University of Wisconsin, Madison, have devised an integrated flow-reactor system for converting the versatile biomass-derived feedstock γ-valerolactone into ready-to-use gasoline and jet fuel (Science 2010, 327, 1110). The Wisconsin team’s method improves downstream processing of γ-valerolactone by first using a silica-alumina catalyst to open the ring and decarboxylate aqueous γ-valerolactone to a mixture of butenes and CO2. The butenes are subsequently strung together by using an amberlyst catalyst to form octenes and higher alkene oligomers with molecular weights and branching that can be selectively formulated as gasoline or jet fuel. The new approach provides several bonuses. It avoids costly precious-metal catalysts and doesn’t require an external source of H2. And although the process generates CO2 as a by-product, the reactor design allows the CO2 to be trapped as a relatively pure, pressurized stream that could be readily sequestered or used to make methanol or polycarbonates.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter