Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

New Applications For Glass Emerge

As current as smartphones, as eternal as ancient Chinese tea sets, glass enjoys a clear advantage in many applications

by Mitch Jacoby

June 18, 2012

| A version of this story appeared in

Volume 90, Issue 25

Like other materials that have been known and used for millennia, glass is sometimes taken for granted. Yet this age-old material plays a central role in numerous applications—and not just classic ones like architecture, windows, lenses, bottles, and containers.

In fact, “glass is one of the enabling materials in electronics, communications, sensing, medicine, nuclear waste storage, and many other fields,” said John Ballato, a Clemson University materials science professor and fiber-optics specialist.

As a result of glass’s widespread use and broad commercialization, the field of glass science and technology is thriving. The field’s liveliness was evident from conference room discussions and coffee-break chatter at last month’s meeting of the Glass & Optical Materials Division of the American Ceramic Society (ACerS) in St. Louis.

According to Ballato, who chairs the nearly 100-year-old division, the meeting brought together some 300 scientists from academia, national labs, and industry, and included world-class glass specialists from 20 countries. This eclectic group of solid-state chemists, physicists, materials scientists, geoscientists, and engineers reported on seemingly unrelated topics in basic glass science, biomedical materials, electronics and photonics, and archaeology. The presentations, of course, were related by the researchers’ common focus on glass—mainly the inorganic oxide variety.

Part of the reason for glass’s popularity in disparate technical applications is its adaptability. “The great thing about glass,” according to Richard K. Brow, “is that you can tune the composition to customize the chemical and physical properties of the glass, and then process it into all kinds of shapes.” Brow, ACerS president-elect and a materials science professor at Missouri University of Science & Technology (Missouri S&T), Rolla, elaborated on that comment. He explained that, depending on application, glass is prepared as small or large sheets, micro- or macroscopic spheres, and fibers with a wide range of diameters, lengths, and textures. Like Ballato, Brow quickly came up with a list of applications spanning numerous areas of technology.

One handy-sized application of chemically tailored glass sheets is the display material found in cell phones and other portable electronic devices with touch screens. Glass and ceramics giantCorning, for example, uses an ion-exchange process to boost the toughness and scratch resistance of sodium aluminosilicate glass to make its Gorilla Glass line of products (C&EN, March 26, page 28).

The ion-exchange reaction swaps some of the sodium ions at the glass surface with larger potassium ions. The difference in ion size leads to compressive forces that toughen the surface by shutting down avenues along which cracks could otherwise propagate. According to Corning, its toughened glass is used in more than 750 models of smartphones, tablet and slate devices, notebook computers, and other products.

A similar glass-toughening ion-exchange process lies at the heart of chemical treatments developed by Arun K. Varshneya for a biomedical application—strengthening glass cartridges used in epinephrine injectors. Varshneya, a professor of glass science and engineering at Alfred University, in Alfred, N.Y., and a regular ACerS glass meeting attendee, founded Saxon Glass Technologies in the mid-1990s to commercialize the process. The company has produced millions of tough glass cartridges for the EpiPen brand of injectors, which are designed for self-administration of epinephrine to treat life-threatening allergic reactions.

Glass plays a key role—even the central role—in several other biomedical applications discussed at the meeting. Perhaps the one mentioned most frequently during the weeklong conference is a radioactive yttrium aluminosilicate (YAS) glass that’s prepared as microspheres and used to destroy malignant tumors. The microspheres were developed by Delbert E. Day, emeritus professor of materials science at Missouri S&T, and commercialized by Mo-Sci, a company he cofounded.

Developing the microspheres and gaining approval from the Food & Drug Administration to use them to treat tumors was a lengthy affair partly because of the long list of requirements that need to be satisfied for this application. Among other requirements, the material must be biocompatible and nontoxic to the body (except for the tumor), readily formed into the desired size and shape, and deliverable directly to the diseased organ. For an inoperable form of liver cancer known as hepatocellular carcinoma, YAS spheres with roughly 30-μm diameters fit the bill and work effectively.

Briefly, 90Y, a β-emitter with a 64-hour half-life, is produced via neutron activation of naturally abundant 89Y. The spheres are typically delivered on an outpatient basis via the hepatic artery and as a result of their size and shape, become lodged in tumor capillaries. Studies show that the radiation penetrates only about 2.5 mm into soft tissue, resulting in minimal damage to healthy portions of the liver.

Steven B. Jung, a senior R&D engineer at Mo-Sci, reported on the company’s progress in developing DermaFuse, an inexpensive cottonlike bioactive borate glass. The novel nanofibrous material is undergoing clinical evaluation for healing large and deep wounds, including chronic skin ulcers and other persistent conditions. Bioactive glasses have been studied and used for more than 40 years, mainly for hard-tissue (bone) repair and regeneration, Jung noted. Glass-based treatments for soft tissues (skin and muscle), however, have received relatively little attention, he pointed out, even though hard and soft tissues heal by way of similar mechanisms.

Shortly after healthy patients sustain an injury, fibrinogen and thrombin react to form a polymerized mesh that clots the wound site. That process keeps out microbes and stimulates release of growth factors, which ultimately leads to cell proliferation and tissue repair. These natural healing processes are often impaired in patients suffering from poor circulation, diabetes, vascular diseases, and other chronic health conditions. As a result, when these people suffer serious injury, the wound often goes unhealed for months and the patient’s condition deteriorates.

Jung summarized results of an ongoing clinical trial involving 58 patients whose skin ulcers and similar nonhealing wounds were dressed every few days with DermaFuse. As of last month, 47 patients’ injuries—including golf-ball-sized open wounds—were healed, he reported. He proposed that the high success rate may be attributed to the material’s antimicrobial properties, its release of bioactive ions that stimulate blood vessel growth, and its fibrous network, which traps blood platelets and mimics blood clot microstructures.

Metal-free restorative dentistry is yet another health-related application of glass-based materials. Wolfram Höland, head of inorganic chemistry R&D at Lichtenstein-based Ivoclar Vivadent, a major dental materials manufacturer, presented an overview of the development of glass-ceramics, a group of materials that are produced through controlled crystallization processes and share some properties with glasses and others with ceramics.

As a class of materials, glass-ceramics are strong and can provide aesthetically pleasing results, Höland noted, which makes them well suited to dental restoration applications. Materials based on leucite (KAlSi2O6), for example, have long been used to fabricate inlays and crowns, and lithium disilicate (Li2Si2O5), as a result of its increased flexural strength relative to leucite, broadened the range of glass-ceramic applications to include dental bridges. Fluorapatite (Ca5(PO4)3F) is another glass-ceramic used in dentistry. According to Höland, needlelike crystals formed by that material endow it with light-scattering properties that cause its translucency to match that of natural teeth.

In the dental materials arena, light scattering can be a good thing. In other topics discussed at the meeting—chemical detection via infrared spectroscopy, for example—light scattering is an impediment to achieving high sensitivity. One way to sidestep that problem is to irradiate a sample with IR light, but instead of measuring the IR spectrum, record the sample’s photothermal spectrum, which is a measure of heat-induced effects such as a change in temperature, density, or refractive index.

At the University of Delaware, materials scientists Juejun Hu and Hongtao Lin are working to maximize photothermal sensitivity to be able to detect single gas-phase molecules. Their strategy is to generate the analytical signal in a light- and heat-confining nanometer-sized cavity in chalcogenide glasses. That family includes S-, Se-, and Te-based materials such as GeSbTe, AgInSbTe, and various In-S and In-Se compounds. Those glasses are ideal for this application, Lin explained, because of their low thermal conductivity, large refractive index, and high thermo-optic coefficient. Hu, Lin, and Zou Yi just published a detailed description of their detector design in Optics Letters and concluded on the basis of a numerical analysis that it indeed has the potential to detect single gas-phase molecules (DOI: 10.1364/ol.37.001304).

TEATIME

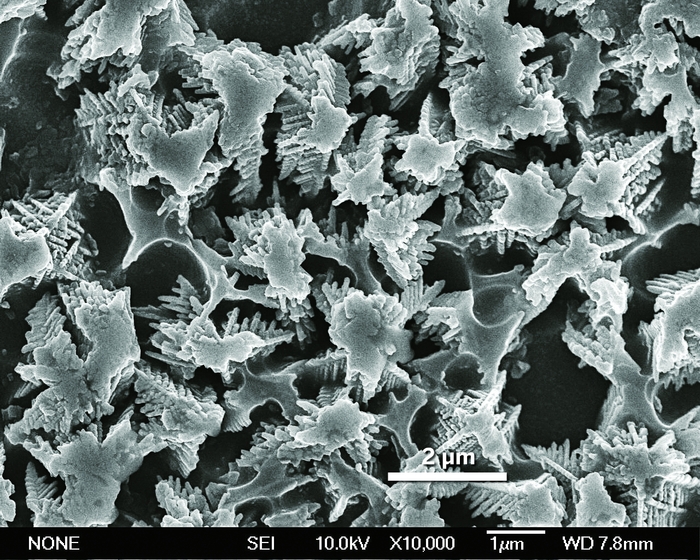

Ancient Chinese tea bowls from the Song Dynasty are often decorated with a streaked “hare’s fur” glaze pattern, which results from the layered ordering of micrometer-sized snowflakeshaped iron oxide precipitates shown in this SEM image.

Credit: Weidong Li/Shanghai Inst. of Ceramics, Fujian Museum

While some researchers focus on new glass formulations for future applications, others study ancient ones. Weidong Li of Shanghai Institute of Ceramics together with coworkers at China’s Fujian Museum have been working to uncover the origin of the decorative patterns of streaks (“hare’s fur”) and spots found on glazed tea bowls unearthed from the Jian Kiln site in southern China. Now prized collector’s items, the bowls, which were used in traditional tea-tasting ceremonies, hail from the Song Dynasty (A.D. 960–1279) and were manufactured via long-lost techniques.

On the basis of microscopy and spectroscopy analysis, the group finds that the streaks and spots are iron oxide crystallites that precipitate during formation of the K-Ca-Mg-Fe oxide aluminosilicate glaze. The precipitation mechanisms are complex. For example, Li noted that some samples bear evidence that oxygen bubbles generated by pyrolysis of Fe2O3 rose to the glaze surface, dragging bits of anorthite (CaAl2Si2O8) and Fe2O3 with them. The firing treatment caused the low-viscosity, iron-enriched material to flow, form streaks, and eventually cool and precipitate between anorthite crystals. “Based on our study, we have been able to make good replicas of Jian bowls,” Li remarked.

Continuing with the archaeology theme, Denis Strachan of Pacific Northwest National Laboratory reported on the status of an in-progress glass experiment, one that’s been running for about 2,000 years. Standard lab tests probe samples over relatively short timescales. But Strachan wants data from long-term tests. So he has been studying glass samples recovered from the Iulia Felix, a Roman ship that sank in the Adriatic Sea between A.D. 150 and 250. Strachan’s aim is to understand details of glass corrosion, dissolution, ion exchange, and other decomposition processes to construct a model that will accurately predict the fate of glass-entombed radionuclides over roughly 1 million years, the period needed for safely storing some types of nuclear waste.

Various types of analyses, including ones based on atom-probe tomography, which provides three-dimensional chemical maps with nanoscale resolution, show evidence of extensive ion exchange and other compositional changes in samples from the Iulia Felix. To help construct and validate the glass corrosion model, Strachan and coworkers are now comparing those samples with other specimens of similar age that were exposed to other environmental conditions.

Perhaps because glass is so ubiquitous, so “right in front of you” with 1,001 uses, it risks going unnoticed by people unaccustomed to thinking about its properties—even scientists. Despite its potential for keeping a low profile, glass science and technology is a bustling field.

“Glass has been around for 5,000 years, and yet there still are many things we don’t understand about its properties,” Ballato stressed. But scientists are constantly adding to the knowledge, and with so many new discoveries, new materials, and new applications reported regularly, glass science is sure to stick around for a long time to come.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter