Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Simple Nanopowders For Electrolysis

Easy-to-process Ni–Mo powders can be cast onto electrode substrates and used as an efficient hydrogen-evolving catalyst

by Elizabeth K. Wilson

January 14, 2013

| A version of this story appeared in

Volume 91, Issue 2

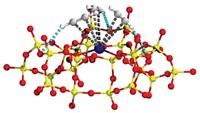

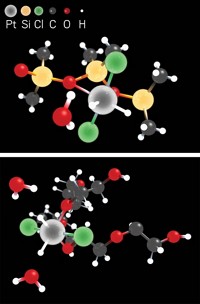

A nickel-molybdenum catalyst to generate hydrogen from water can now be synthesized as a nanopowder, greatly improving its processability and allowing it to be studied in better detail (ACS Catal., DOI: 10.1021/cs300691m). James R. McKone, Harry B. Gray, and colleagues at Caltech prepared the Ni-Mo nanopowders in a two-step process, starting with an aqueous solution of nickel hexammine and ammonium molybdate. Heating the mixture in diethylene glycol produced a mixed Ni-Mo oxide precipitate, which was isolated and reduced with hydrogen to generate the Ni-Mo nanopowder. Scientists are developing nickel- or steel-based catalysts for the hydrogen evolution reaction because they are much cheaper than and nearly as active as traditional noble-metal electrocatalysts. The Caltech researchers found that the new powders can be suspended in solvents and, without a support material, be cast as layers onto electrode surfaces. Among other techniques, they used electron microscopy to determine that the catalyst material’s high porosity contributes to its activity.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter