Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Papermaking Waste Could Fix BPA Problem

ACS Meeting News: Chemical engineers develop bisguaiacol F from lignin waste as a replacement for bisphenol A

by Bethany Halford

March 24, 2014

| A version of this story appeared in

Volume 92, Issue 12

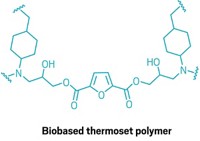

Lignin waste and the dangers of bisphenol A (BPA) seem like two unrelated problems. But not to Richard P. Wool and Kaleigh H. Reno. Instead, the University of Delaware chemical engineering professor and graduate student, respectively, see the first problem as a solution to the second. Every year, the pulp and paper industry produces millions of tons of lignin waste as a by-product. This material is usually incinerated. But a group led by Wool and Reno have developed a process for turning two aromatic alcohols that make up lignin—vanillyl alcohol and guaiacol—into a compound that could be used to replace BPA as a monomer that provides rigidity to plastics. The compound, bisguaiacol F, is structurally similar to BPA, but it has some differences, including two pendant methoxy groups. These groups, the researchers said, should keep bisguaiacol F from binding to estrogen receptors, where scientists think BPA wreaks havoc. The Delaware researchers used Environmental Protection Agency software to evaluate bisguaiacol F for safety and Wool’s twinkling fractal theory of the glass transition to predict that its mechanical and thermal properties would be similar to those of BPA.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter