Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Better Packaging Through Chemistry

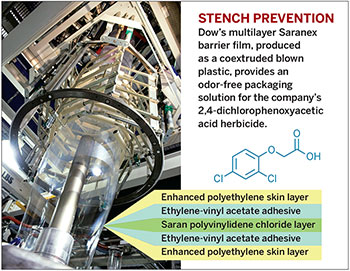

Dow Chemical solves a pungent predicament by developing a barrier film to contain a popular herbicide’s noxious smell

by Stephen K. Ritter

June 23, 2014

| A version of this story appeared in

Volume 92, Issue 25

The chemistry taking place every day in all corners of the world isn’t always glamorous, but it often is practical. That’s the case with a technical innovation at Dow Chemical in which a collaborative team developed an odor-barrier film for packaging the blockbuster herbicide 2,4-dichlorophenoxyacetic acid.

Known as 2,4-D, the herbicide is deemed safe when handled as directed for approved uses. But the chemical has a pungent odor that can be bothersome to employees and that has elicited complaints from people living near production and storage facilities. The odor-free packaging solution is but one example of how cross-functional, multidisciplinary teams at Dow and other chemical companies regularly come together to tackle supply-chain challenges.

2,4-D is a broad-spectrum herbicide that Dow has produced for decades and uses in many agricultural and lawn and garden product formulations. The compound is a synthetic analog of the plant growth hormone auxin (indole-3-acetic acid). Treating weeds with 2,4-D triggers uncontrolled growth that kills the plants.

The herbicide became well-known in the 1960s for being one of the two active ingredients in Agent Orange, a controversial defoliant used by the U.S. during the Vietnam War. The second ingredient, 2,4,5-trichlorophenoxyacetic acid, was found to contain a toxic dioxin contaminant and was banned. In contrast, 2,4-D has withstood repeated toxicity reviews by the Environmental Protection Agency.

Dow has more recently developed genetically modified corn and soybeans resistant to 2,4-D, which the company anticipates will gain regulatory approval and be available in 2015. With higher production volumes of 2,4-D expected, Dow decided to step up and address the pungent-odor problem.

The herbicide was being packaged in an inexpensive 3-mil-thick polyethylene plastic liner within a woven polypropylene flexible industrial bulk container, explains chemical engineer Michael L. Mounts, development leader for Dow’s packaging and specialty plastics business unit. “The plastic liner doesn’t have a very good odor barrier—and the herbicide has a strong odor,” Mounts says. “There’s also an economic component to this story: Each container had to be washed in a special cleaning step after transporting the product to get the odor out so the containers could be reused.” Cleaning the packaging material took time and squandered resources, thereby going against the grain of Dow’s sustainability goals.

A Dow AgroSciences team tried several commercially available solutions for repackaging 2,4-D, including a laminated foil wrapper and an ethylene-vinyl alcohol plastic liner, Mounts notes. But those packaging options were more costly and still didn’t corral the stink, he says.

One day a member of the Dow AgroSciences team who previously worked in the Dow Performance Packaging business recognized that Dow’s Saranex barrier films might provide a solution. These multilayered materials have proved their mettle in a variety of odor-barrier applications, including meat and cheese food packaging, medical packaging, and even protective clothing. Mounts and his colleagues decided to give a customized Saranex film a shot.

Saranex is produced as a coextruded blown film, Mounts explains. The film’s core is made from polyvinylidene chloride—Dow’s famous Saran wrap polymer. The outer skin layers are a tough, impervious polyethylene elastomer blend that includes Dow’s Affinity polyolefin. The three layers are held together by an ethylene-vinyl acetate polymeric adhesive. As soon as the bulk containers were lined with the new 3-mil-thick barrier film, warehouses reported an immediate improvement in the 2,4-D odor situation, Mounts says.

“What they have done is great,” says food scientist Sara J. Risch of packaging consulting firm Science by Design. Saran was one of the first films developed as a barrier to not only water vapor and oxygen but also aromas, she notes. This new multilayer film, which is no longer a simple polyethylene sheet, may not be as environmentally friendly as the original packaging, Risch says. “But it will provide a much greater benefit in virtually eliminating any odor.”

“The Saranex product has a potentially bright future,” adds Dan Schnaars Sr., copresident of AmeriGlobe, which manufactures the bulk containers Dow buys to use for packaging 2,4-D. Replacing more expensive liners made by other companies with Saranex lowered the cost of repackaging the herbicide, Schnaars says, and that is actually money back to Dow’s bottom line.

And as AmeriGlobe expands sales of the film for additional applications and customers, Dow’s benefit will grow, he notes. “This is a great example of how moving technology forward for one particular gain can continue to pay unexpected dividends.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter