Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Solvent Engineering Improves Solar Cells

Depositing perovskite layers with a multisolvent system improves thin-film quality and boosts device performance

by Mitch Jacoby

July 14, 2014

| A version of this story appeared in

Volume 92, Issue 28

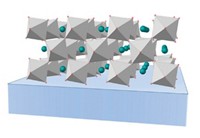

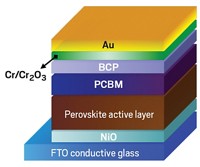

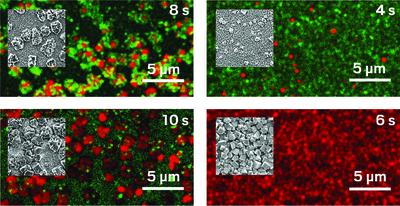

By devising a multisolvent method for producing highly uniform perovskite thin films, researchers in South Korea have come up with an improved way to make inexpensive high-performance solar cells (Nat. Mater. 2014, DOI: 10.1038/nmat4014). Perovskite-based solar cells, which feature a sunlight-absorbing organometal halide with the perovskite crystal structure, are layered devices typically made via spin-coating, a simple solution-phase film-deposition method. But that method yields perovskite films that don’t perfectly coat the underlying surface, thereby limiting light-to-electricity conversion efficiency. Vacuum deposition is an alternative method that boosts film quality and device performance, but it raises costs. Those challenges led Sang Il Seok and coworkers at Korea Research Institute of Chemical Technology to devise a solvent-processing method that yields more uniform films and leads to conversion efficiencies on par with the best vacuum-deposition perovskite cells reported to date. The team starts by spin-coating a solution of methyl ammonium halides and lead halides in a mixture of γ-butyrolactone and dimethylsulfoxide solvents. During the spinning process, the team adds a third solvent in which the perovskite-forming reagents are insoluble, such as toluene or chloroform, dropwise on the spreading layer. That extra step helps stabilize an intermediate phase, which the researchers heat to yield the desired uniform perovskite film.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter