Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Ball Mill Grinds Monomers Into Polymer

Polymer Chemistry: Chemists use ball-milling to synthesize the conductive polymer poly(phenylene vinylene) without solvent

by Louisa Dalton

April 1, 2014

Smashing compounds together to get them to polymerize sounds more like desperation than effective organic chemistry. But chemists Timothy M. Swager of Massachusetts Institute of Technology and Jens B. Ravnsbæk, now of Aarhus University, in Denmark, have demonstrated that the technique works. They polymerized poly(phenylene vinylene) (PPV)—a conductive polymer used in organic light-emitting diodes—in minutes inside a ball mill, which grinds the reactants together (ACS Macro Lett. 2014, DOI: 10.1021/mz500098r). They say the process is fast, requires no solvent, and yields more consistent chain lengths than wet-chemistry synthesis.

Chemists commonly use ball mills to grind materials into powders and mix them together, yet few groups use the mechanical energy of a mill to chemically bond molecules, Swager says. Using mechanochemistry to create polymers is particularly unusual, he adds, because ball mills are known to break down polymer chains.

But Swager and Ravnsbæk wanted to try polymerizing PPV through grinding together monomers, partly because the traditional, solvent-based synthesis is difficult to control. “We do it in undergrad lab at MIT, and every student gets a different result,” Swager says. The polymer chains produced can have molecular weights from a hundred thousand to a million daltons.

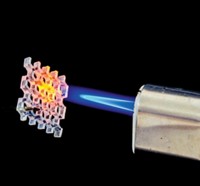

To test the mechanochemistry route, the chemists placed the monomer of poly(2-methoxy-5-2´-ethylhexyloxy phenylene vinylene), which is a white powder, in a ball mill with some tert-butoxide base to initiate the polymerization reaction. After only a few minutes of milling, they were pleased to see the bright red PPV powder form. Ten minutes in the mill resulted in greater than 60% yield and polymers that averaged 35 kDa in size. The milling process, the researchers confirmed, breaks up any longer polymer chains that form.

Swager says the synthesis is a reliable, consistent way to make polymers of this length. His group is now developing ways to use ball mills to add functional groups to polymers and to create nanomaterials without using solvent.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter