Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biomaterials

Sewing hydrogels together to make them stick

In situ polymerization creates polymer threads that weave in and out of hydrogels

by XiaoZhi Lim, special to C&EN

August 8, 2019

| A version of this story appeared in

Volume 97, Issue 32

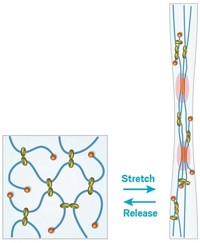

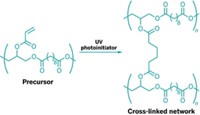

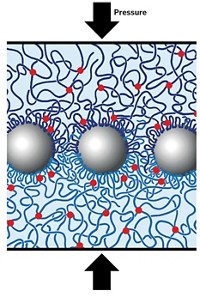

Hydrogels, biocompatible cross-linked polymer networks, could be useful in artificial muscles or cartilage. But they don’t stick well to each other or to living tissues, which limits their use in the body. Shingo Tamesue of Utsunomiya University and colleagues report a solution that resembles sewing fabrics together (Macromolecules 2019, DOI: 10.1021/acs.macromol.9b01084). The team used in situ polymerization reactions to grow polymer threads that weave in and out of hydrogel pieces, binding them together. The researchers first soaked two slices of the polyacrylamide hydrogel in a solution of acrylamide monomers and the radical initiator ammonium peroxodisulfate. They then coated the hydrogels’ surfaces with tetraethylmethylenediamine, which accelerates polymerization of acrylamide to form threads, and quickly pressed the surfaces together. After an hour, they were stuck so tightly that one of the hydrogel slices ripped when the researchers tried to peel them apart. In further tests, the researchers adhered polyacrylamide to another type of hydrogel and to slices of chicken liver. They also used other thread materials formed with nonradical polymerization that may be more biocompatible than ones involving free radicals, Tamesue says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter