Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Poly(Glyceric Acid Carbonate) Is A Degradable Analog Of Poly(Acrylic Acid)

Polymer Design: Addition of carbonate linkages gets around some of poly(acrylic acid)’s limitations

by Celia Henry Arnaud

September 28, 2015

| A version of this story appeared in

Volume 93, Issue 38

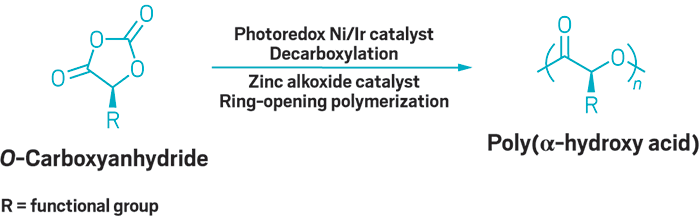

Poly(acrylic acid)s make up a versatile class of polymers that are produced at large scales and used in many applications. But the polymers have some drawbacks. Their all-carbon backbone means that they don’t degrade easily, and their water solubility makes them difficult to recover. Mark W. Grinstaff and coworkers at Boston University have now made analogs with degradable carbonate linkages built into every repeating unit that get around these problems. The researchers synthesized poly(glyceric acid carbonate)s via the ring-opening copolymerization of a benzyl glycidate with CO2 in the presence of bifunctional cobalt salen catalysts to yield benzyl-protected polymers (J. Am. Chem. Soc. 2015, DOI: 10.1021/jacs.5b07911). Removal of the benzyl protecting groups via palladium-catalyzed hydrogenolysis yields the desired polymer. In deionized water, the poly(glyceric acid carbonate) degrades into glyceric acid and CO2 with a half-life of about 12 days, whereas poly(acrylic acid) doesn’t degrade at all. Similarly, a hydrogel made by cross-linking poly(glyceric acid carbonate) with poly(ethylene glycol) and aziridine degraded more rapidly than the corresponding poly(acrylic acid) hydrogel. The new polymers could be useful for a wide range of chemical, biomedical, and pharmaceutical applications, the researchers propose.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter